In the process of ventilation, not only the exhaust air, but also part of the thermal energy is utilized from the room. In winter, this leads to an increase in energy bills.

Reducing unnecessary costs, not to the detriment of air exchange, will allow heat recovery in centralized and local-type ventilation systems. For the regeneration of thermal energy are used different types of heat exchangers - recuperators.

The article describes in detail the models of units, their design features, principles of operation, advantages and disadvantages. The stated information will help in choosing the best option for arranging the ventilation system.

The content of the article:

- The concept of recovery: the principle of operation of the heat exchanger

- Feasibility of a heat exchanger in ventilation

-

Features of different types of heat exchangers

- Plate Heat Exchanger - Simple Design

- Rotary heat exchanger - high system efficiency

- Associated heat exchangers - glycol model

- Chamber knot - universality of application

- Heat pipes - closed heat exchange system

-

Ways of organizing recuperative ventilation

- Centralized complex - air handling unit

- Local units - addition to the existing ventilation system

- Conclusions and useful video on the topic

The concept of recovery: the principle of operation of the heat exchanger

Translated from Latin, recovery means a refund or return. Regarding heat exchange reactions, recovery is characterized as a partial return of energy expended on carrying out the technological action for the purpose of application in the same process.

AT ventilation system The principle of recuperation is used to save thermal energy.

By analogy, cooling is recovered in hot weather - warm supply masses heat the output "mining" and their temperature decreases.

Image Gallery

A photo of

Heat recovery in ventilation systems reduces the cost of maintaining them, maintaining regulatory air exchange.

It is reasonable to use installations for recovery in organized ventilation systems with mechanical induction of air movement.

Recuperators of ventilation systems are located in the attic or in a separate utility room so that sound working equipment did not interfere with tenants of houses, visitors of sports complexes and workers of industrial workshops

Recovered air flow with a portion of fresh air mixed with it is supplied to the premises through the ventilation duct

When arranging industrial premises with ventilation circuits while preserving the received heat and mixing fresh air flow treatment equipment is installed in the attic space, air ducts are suspended under ceiling

In addition to the reuse of heat, the ventilation system equipment filters the air mass, removing dust and toxic components from it.

The heat exchangers currently produced are equipped with devices to reduce energy consumption, which significantly reduces energy consumption.

Recovery is an economical solution for forced ventilation systems, but it is used only as a supplement. The main volume of air in the cold months still handles the heater

Recuperator for ventilation system

Duct duct ventilation system

The location of the recuperator in the attic space

Supply of treated air through the ventilation grill

Ventilation system in the production area

Recuperative Ventilation Spa Salon

Energy Saving Device Installations

Air flow heater in systems

The process of energy recovery is carried out in a heat exchanger. The device provides for the presence of a heat exchange element and fans for pumping multidirectional air flows. To control the process and control the quality of the air supply system is used automation.

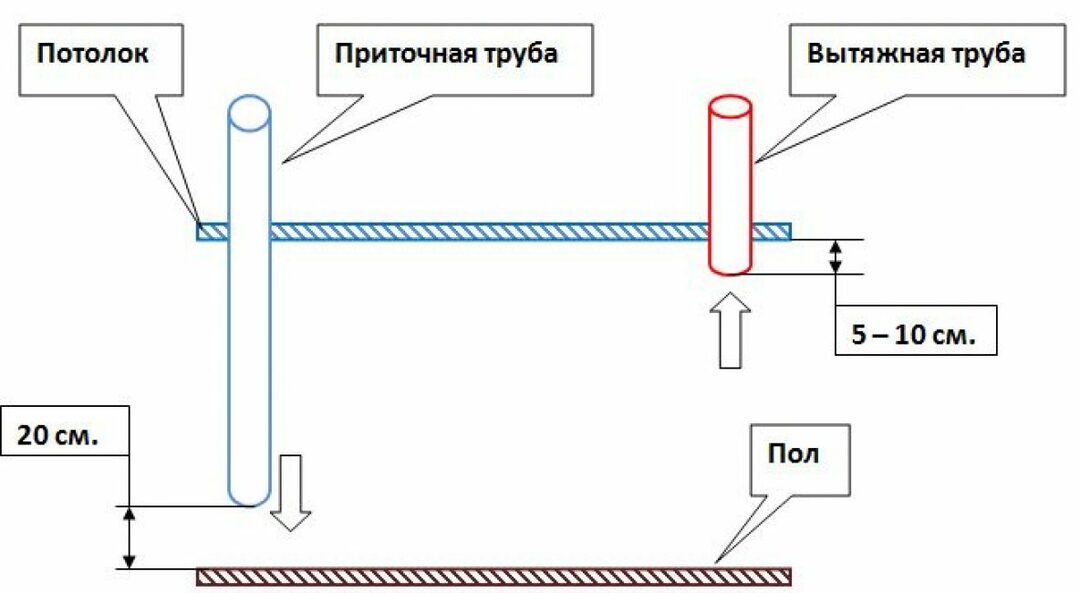

The design is designed so that the supply and exhaust streams are in separate compartments and do not mix - heat recovery is carried out through the walls of the heat exchanger.

Understand and understand what is ventilation with heat recovery help visual scheme of air circulation.

Through the hood in wet areas (toilet, bathroom, kitchen) is the outflow of exhaust air. Before retiring, it passes through the heat exchanger and leaves some heat. The supplied air moves in the opposite direction, heats up and enters the living rooms (+)

Feasibility of a heat exchanger in ventilation

It is possible to speak about the expediency of arranging recuperative ventilation by assessing the effectiveness of the system and comparing its advantages with disadvantages.

Part of the heat is drawn from the exhaust air drawn out to the outside and transferred to the injected fresh jets directed inside the room. This reduces heat loss by up to 70% (+)

The need to use heat recovery is most relevant in buildings with forced air outlet. As a rule, these are low-inertial structures erected with the use of innovative heat-insulating technologies (houses made of sandwich panels, gas silicate slabs, foam blocks).

In such buildings, the walls accumulate heat poorly, and natural air exchange is ineffective.

However, problems with air circulation are also characteristic of “traditional” brick and concrete structures. The presence of hermetic heat-insulating PVC windows blocks circulation with natural impulses - the flow of fresh air stops and traction in the cannon overturns or tends to zero.

The solution to the problem of "eurowindows" is the organization of forced ventilation. The system restores air exchange, but at the same time heat losses increase to 60%. And here we can not do without thermal recovery.

The efficiency of the exchange process is expressed as a percentage and shows the amount of heat expended from the exhaust air to heat the fresh "influx"

Indicator of efficiency of ventilation heat recovery:

- 0% - an open window - warm air is removed into the atmosphere, and the cold gets inside, lowering the temperature in the room;

- 100% - supply air is heated to the temperature of "working out" - it is technically impossible to implement;

- 30-90% - permissible parameter, good recovery is considered with an efficiency of 60% or more, Efficiency above 80% is an excellent heat exchange.

The efficiency of the system depends on the type of heat exchanger, room dimensions and air flow. In any case, the use of recovery ventilation, even with an efficiency of 30% more profitable than its absence. In addition to significant savings in energy, the "regeneration" of heat improves the overall microclimate in the room.

Disadvantages of using a heat exchanger:

- Volatility. The purchase of climate equipment is justified if the power consumption will be significantly less than its savings after the installation of the heat exchanger.

- Condensation Due to the temperature difference on the walls of the heat exchanger moisture may condense. In winter, there is a chance of icing, which is fraught with a rapid decrease in efficiency or the failure of the heat exchanger.

- Noisy work. Some models in the process of operation emit a drone. If during the day this deficiency is not particularly noticeable, then at night the noise brings discomfort. Recuperators with improved insulation work quietly.

High initial investment often becomes the main argument against energy efficient ventilation.

It is advisable to invest in the system that pays off within 5-8 years. It should be noted that for the maintenance of the complex will have to incur additional costs, for example, periodic replacement of fans

Features of different types of heat exchangers

The design of the heat exchanger determines the flow pattern of the coolant, the efficiency of the ventilation system, the class of energy consumption and the cost of equipment. Five variants of heat exchangers are used: lamellar, rotary, heat pipes, chamber devices and models with intermediate coolant.

Plate Heat Exchanger - Simple Design

The basis of the heat exchanger is an airtight chamber with multiple parallel ducts. The channels are separated by partitions - heat-conducting plates made of steel or aluminum.

Wavy plates (60-70 pieces) are grouped in one block so that the formed channels are located crosswise to each other - the created turbulence improves heat transfer (+)

Gas flows move towards each other, intersect in the heat exchanger cassette, but do not mix. Heat exchange is carried out by simultaneous cooling and heating of the plates from different sides.

Advantages of the cross heat exchanger:

- easy installation and configuration of equipment;

- exception of contact of air masses;

- affordable cost and compact dimensions;

- no rubbing and moving parts.

The efficiency index varies in the range of 40-70%.

The main disadvantage of the lamellar model is the condensate settling in the exhaust duct and the formation of ice in winter. To defrost the unit, the incoming jet is redirected to bypass the heat exchanger, and the warm effluent melts the ice on the plates.

In the “defrosting” mode, energy is not saved, and heaters up to 5 kW are used to heat the incoming air. Average efficiency drops by 20% (+)

There are two ways to solve the problem:

- Preheat the incoming air flow to a temperature at which the formation of ice is excluded.

- Recuperator with absorbent pulp plates. The material absorbs moisture from the waste air masses and transmits it to the newly incoming flows.

When choosing a cross heat exchanger, the operational features of the plates should be taken into account.

Their characteristics depend on the material of manufacture:

- Aluminium foil - affordable cost, but limited performance in winter. In addition, it is not recommended for residential premises due to air drying. Modifications with aluminum "filling" - the best option for baths and pools.

- Plastic dividers - at the price are similar to metal products, but differ in the improved overall performance.

- Cellulose Heat Exchanger - prevent frosting and maintain normal moisture content indoors.

The hygrocellulose recuperator is the most economical and optimal for ventilation of residential buildings.

Rotary heat exchanger - high system efficiency

The heat exchanger is presented in the form of a cylinder filled with corrugated metal interlayers. As the drum unit rotates, warm or cold jets of air alternately enter each compartment.

The design of the rotor heat exchanger: a shaft of rotation and two air channels. One section of the rotor is heated by “working off”, the drum is scrolled and the heat is redirected to cold masses concentrated in the adjacent channel (+)

The efficiency of heat transfer is determined by the speed of rotation of the rotor, the efficiency can be adjusted.

Arguments “for” rotary heat exchanger:

- heat recovery up to 65-90%;

- economy power consumption;

- partial moisture recovery - you can do without a humidifier;

- payback period - up to 4 years.

Despite its high efficiency, a drum-type heat exchanger did not become a leader among similar installations.

Cons of the ventilation system:

- Mix the polluted air into the inflow. The exhaust and inflow masses alternately circulate through the microchannels, so about 3–8% of the “working off” come back. The drum often conveys the smell of outgoing air.

- The complexity of the design. The rotating parts of the rotor need regular maintenance and periodic replacement. Moving elements during operation produce noise and vibration.

- High price. The price for rotary models is higher than for lamellar products. This is due to the use of complex mechanics in the design of the drum heat exchanger.

- Big sizes. Installation is carried out in a spacious ventilation chamber.

Due to the bulkiness of the rotor installation are used mainly in industrial plants.

To minimize air flow mixing, the rotor recuperators are supplemented with intermediate sectors - here the microchannels are blown with fresh air, which flows back into the hood. Minus scheme - reduced efficiency (+)

Associated heat exchangers - glycol model

The heat recovery unit with intermediate coolant is often referred to as associated heat exchangers or a glycol unit due to its design features. This is one of the most flexible heat recovery systems. One heat exchanger crashes into the inlet duct, and the second into the exhaust.

In the piping scheme there are: a circulation pump, an expansion tank, an air valve, a controller, a temperature sensor, a safety valve, a pressure indicator (+)

Principle of operation. The glycol composition is circulated between the heat exchangers. The temperature of the coolant increases due to the heated exhaust stream, and then the heat energy is transferred to fresh air. A closed system eliminates mixing of oncoming air masses.

Features of operation of heat exchangers with coolant:

- Efficiency - 45-55%;

- efficiency adjustment using a pump - antifreeze movement speed is selected;

- the possibility of placing supply and exhaust air ducts remotely from each other (up to 800 m);

- installation of the heat exchanger is carried out vertically or horizontally;

- in severe frost, the surface of the exhaust heat exchanger frosting - ice appears; the use of antifreeze allows the recuperator to be operated without resorting to defrosting;

- the payback period of the system is up to 2 years;

- A combination of 1 hood and several tributaries is allowed, or vice versa.

The volume of air removed and injected should be approximately equal. Such heat exchangers are usually used if the flow is toxic or heavily polluted when mixing flows is unacceptable.

Chamber knot - universality of application

Structurally, the chamber heat exchanger is a closed box divided inside a moving damper. The opening partition defines the operation of the heat exchanger.

The outflow runs along one channel, and the inflow enters the second chamber. In the heat exchanger, warm masses heat the walls of the first compartment. After a while, the flap moves and the air flow changes direction.

As a result, the inflow moves along the warm walls of the first air duct, and “working out” heats the surface of the second chamber. At some point, the partition becomes back and the cycle repeats.

Advantages of the chamber heat exchange unit:

- Efficiency - 80-90%;

- in tandem with high-quality thermal insulation heating costs are minimized;

- ease of installation - the help of specialists will be needed when choosing the parameters of the ventilation unit;

- preservation of humidity levels;

- system freezing is excluded.

Chamber heat exchanger is an excellent option for regions where during the year a long period there is a significant imbalance between the temperature inside and outside.

The disadvantages of the heat recovery unit include:

- the need for regular maintenance of moving parts;

- oncoming air streams are partially mixed - odors and impurities can flow back into the building.

To reduce the mix, the system is completed filter element. The air becomes cleaner, but the efficiency of the recuperator falls.

Heat pipes - closed heat exchange system

The recuperator consists of a variety of copper or aluminum tubes filled with volatile matter, such as freon. The principle of operation of a tubular heat exchanger is based on physical processes - a change in the state of a substance when heated.

The thermotube is placed vertically - the lower end of the heat exchanger in the exhaust duct, and the top - in the intake duct. Outgoing flows round the end of the tube - freon heats up, boils and evaporates (+)

The gas rises and releases thermal energy to the inflow, after which the freon is condensed and flows down the heat exchanger. The thermal cycle is repeated in a circle.

Technical and operational characteristics of the tubular heat exchanger:

- device efficiency - up to 65%;

- quiet operation due to the absence of moving parts;

- simplicity of design and unpretentiousness in service;

- compactness - small dimensions and low weight;

- energy independence - the coolant circulates naturally;

A weighty advantage is that the air flow and return flow are not mixed.

Weaknesses of heat pipes:

- high efficiency achieved at a narrow temperature range - with a sharp overheating, all the freon evaporates, and with insufficient heating, the evaporation rate slows down;

- low tube strength - reshaping or depressurization reduces equipment performance.

Tubular heat exchangers are used in private construction, in administrative, office buildings and small industrial areas.

Ways of organizing recuperative ventilation

Recovery is settled in one of the ways: centralized and decentralized. In the first case, ventilation streams from the entire room pass through the heat exchanger, in the second case - from one room.

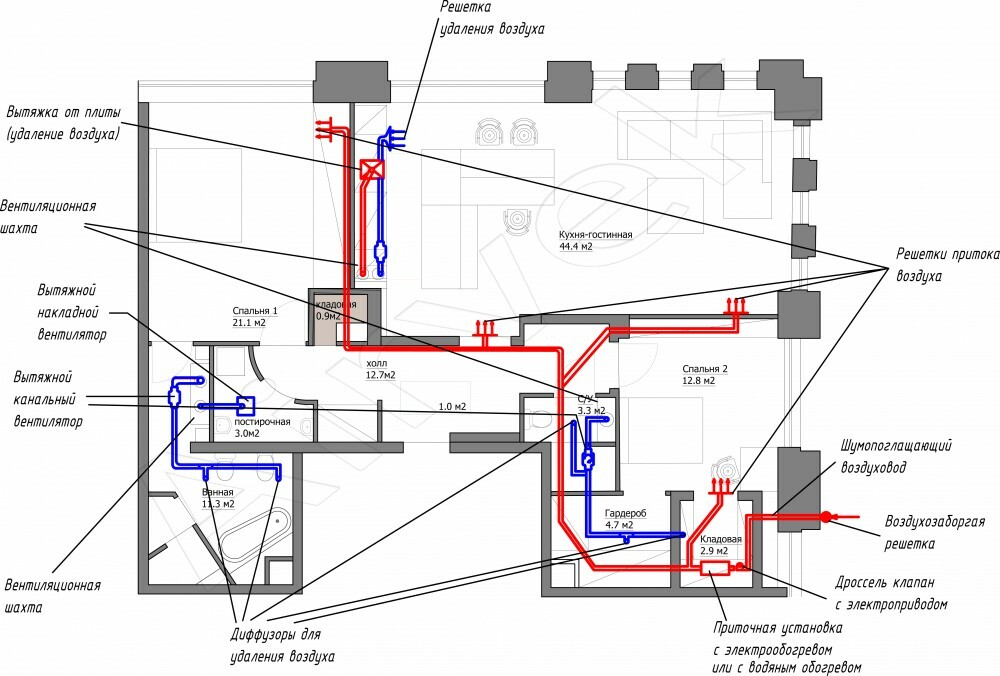

Centralized complex - air handling unit

The centralized system is settled at the stage of construction or capital modernization of the ventilation system.

Forced supply and exhaust unit (PVU) with built-in recuperator is selected. The main selection criterion - the overall performance of the complex based on the entire volume of air in the structure (+)

PVU with a heat exchanger provides sufficient air exchange even in houses with hermetic windows. At the same time air flows are distributed evenly, without creating drafts.

Complex air handling units monoblock type are equipped with:

- fans - round-the-clock supply of clean air and emission of jets saturated with carbon dioxide;

- heaters - pre-heating inflow;

- by filters - detains dust and microparticles;

- heat exchanger - different types of installations may be used.

The functionality of some PWUs has been extended with a delay timer, power regulator, humidity level sensors, and so on.

The case of monoblock models is covered with noise absorbing material, so that the work of the PWU becomes very quiet. Vertical, horizontal and suspended versions of ventilation units are possible.

Well-proven recuperative monoblock PVU production: "Vents" (Ukraine), Dantherm (Denmark), "Daikin" (Japan), "Dantex" (England).

Local units - addition to the existing ventilation system

In order to restore the circulation of air masses in the room being operated, decentralized influxes with heat recovery will be suitable.

They crash into the facade of the building or are mounted through a window. Their main task is to improve ventilation in the House.

A fan and a plate heat exchanger are provided in local recuperators. The “sleeve” of the air cleaner is insulated with noise absorbing material. The control unit of the compact ventilation unit is located on the inside wall.

Features of decentralized ventilation systems with recuperation:

- Efficiency – 60-96%;

- low productivity - the devices are designed to provide air exchange in rooms up to 20-35 square meters;

- affordable cost and a wide range of units, ranging from conventional wall valves to automated models with a multi-stage filtration system and the ability to adjust humidity;

- easy installation - for commissioning does not require laying of air ducts, install wall valve you can own.

Popular manufacturers of local recuperators: Prana (Ukraine), O.Erre (Italy), Blizzard (Germany), Vents (Ukraine), Aerovital (Germany).

Important criteria for choosing a wall outlet: permissible wall thickness, capacity, efficiency of the heat exchanger, diameter of the air channel and temperature of the pumped medium

Conclusions and useful video on the topic

Comparison of the work of natural ventilation and forced recovery system:

The principle of operation of the centralized heat exchanger, the calculation of efficiency:

Design and operation of a decentralized heat exchanger on the example of the wall valve Prana:

Through the ventilation system from the room takes about 25-35% of heat. To reduce losses and efficient heat recovery, recuperators are used. Climatic equipment allows you to use the energy of the waste mass to heat the incoming air.

Is there anything to supplement, or have any questions about the work of various ventilation heat exchangers? Please leave comments on the publication, share the experience of operating such facilities. The form for communication is in the lower block.