Gas boilers Beretta have proven themselves as a source of thermal energy in autonomous heating systems. The units are equipped with a function of self-monitoring of the processes occurring in the units and parts during the operation of the boilers. Equipment malfunctions can be detected by light signals.

Let's analyze the typical malfunctions of the Beretta gas boiler and their elimination. Let's consider in what cases it will be possible to solve the problem on our own. We will find out when for repair operations you will have to call a foreman from the gas service.

We will tell you how to determine the error in the operation of the equipment, about which it independently warns the owner. Let us show you what the combinations of letters and numbers mean in the event of a malfunction on the built-in display or indicators. With this information, you can decide how best to proceed.

The content of the article:

- Common breakdowns of Beretta boilers

- How does the self-diagnosis system work?

- Error codes on the boiler display

- What do the indicator signals mean?

- Conclusions and useful video on the topic

Common breakdowns of Beretta boilers

According to the gas workers involved in the repair and adjustment of Beretta gas boilers, there are several main malfunctions that most often occur in the equipment of this brand:

- There is no flame on the burner, as a result of which the equipment is blocked. This problem can be caused by several reasons, ranging from a blockage to a lack of gas supply.

- Breakdown of the control board. It occurs due to the accumulation of condensation on the board, which leads to its failure. Also, a breakdown of the board can occur due to burnout of parts on it.

- Increase in flue gas pressure. Such a failure can be caused by ice in gas boiler chimney, soot clogging, increased wind force. As a result, the equipment is blocked.

- Breakdown of the self-diagnosis sensor. Also leads to equipment shutdown by the control system.

- Low water pressure when supplied to the heating circuit. The most common cause is a leak or a problem with the expansion vessel.

The statistics collected by experts does not mean that such problems will occur in every Beretta boiler.

Perhaps the problems will not appear at all for a long time, or completely different failures will arise for other reasons. Each malfunction or malfunction in Beretta gas boilers has its own code designation, which is displayed by the control system on the LCD display.

It is necessary to pay attention to malfunctions and malfunctions during the operation of the Beretta gas boiler and eliminate them in a timely manner in order to avoid more serious breakdowns.

Fault identification occurs thanks to a self-diagnosis system that allows you to instantly identify problems when they occur and take appropriate action.

How does the self-diagnosis system work?

In Beretta boilers, the self-diagnosis system consists of a network of monitoring sensors located on the main working units of the units.

After turning on the boiler, the sensors begin to function in a continuous mode, they do not need an additional special start. By the same principle, disconnecting sensors is impossible without stopping or blocking the gas boiler.

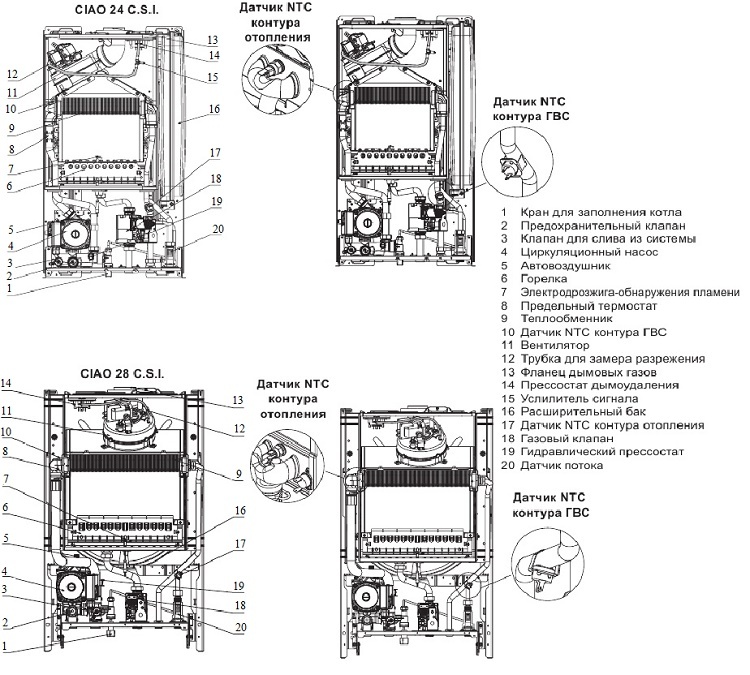

In all the main components of the Beretta gas boiler there are sensors (sensors) that send signals to the display with an error code when a malfunction is detected

When the monitored parameters change or a unit malfunction occurs, signals from the sensors are sent to the control module, which blocks the equipment. At the same time, an error code is shown on the display, allowing the owner of the boiler to determine the type of malfunction and take measures to eliminate it.

In addition to the display, malfunctions of Beretta boilers are signaled by special indicators located depending on the design features of different models of heating equipment.

Error codes on the boiler display

The LCD display, which is equipped with almost all models of Beretta gas boilers, displays information about the operating mode of the equipment, as well as error codes and malfunctions that occur during operation.

Most faults are cleared when the boiler is restarted. But if after rebooting the problem persists, you need to check the parts and assemblies listed below.

The LCD display is located on the control panel of the Beretta gas boiler, in case of failures and malfunctions, error codes are displayed on it, by which you can determine in which unit of the unit there are problems

We have tried to collect the most complete list of errors.

A01 - there is no flame on the burner, 5 unsuccessful attempts to ignite.

Verify:

- the presence of gas in the pipeline;

- position of the boiler shut-off valve;

- adjust the gas valve;

- clean the burner with nozzles;

- ignition electrode, if necessary, clean the contacts;

- ignition relay;

- change the subordinate board.

A02 - overheating of the thermostat.

Verify:

- thermostat, the integrity of the wiring to it;

- clean or replace the circulation pump;

- add fluid at low pressure in the circuit.

A03 - violation of smoke exhaust.

Verify:

- the presence of traction;

- clean gas boiler chimney, if necessary, break off the ice at the exit;

- clean or replace the fan, check the contacts;

- smoke detector, its contacts.

A04 - decrease in water pressure in the system.

Verify:

- presence of leaks;

- pressure sensor, its contacts;

- circulation pump;

- the presence of blockages in the system;

- change the subordinate board.

A05 - breakdown of the NTC temperature sensor for hot water supply.

In order to better understand the cause of the malfunction in the Beretta brand gas boiler, it is advisable to familiarize yourself with the design features of the unit. The device diagram must be in the technical passport

Verify:

- NTC sensor, its connections, if necessary replace the part;

- change the subordinate board.

A06 - breakdown of the NTC heating sensor.

Verify:

- NTC sensor, its connections, replace if necessary;

- change the subordinate board.

A07 - thermostat does not open.

Verify:

- change the subordinate board.

A08-A10 - internal error of the slave board.

Verify:

- change the subordinate board.

A11 - simulation of a flame (fire on a switched off burner).

Verify:

- press Reset, reboot;

- contact the service specialists.

A12, A15 - errors on the slave board.

Verify:

- change the subordinate board.

A16, A18 - errors on the main board.

Verify:

- replace the main board.

A20 - the fire remains after the gas valve is closed.

Verify:

- gas valve, replace if necessary.

A24 - fan malfunction.

Verify:

- fan connection, its contacts;

- in case of breakdown, replace the fan.

ADJ - failure in the min and max power settings.

Verify:

- adjust the parameters you want.

E02 - NTC1 sensor not connected.

Verify:

- NTC1 sensor, its connections, replace if necessary.

E04 - NTC3 sensor not connected.

Verify:

- NTC3 sensor, its connections, replace if necessary.

E18 - short circuit of the NTC1 sensor.

Verify:

- NTC1 sensor connector;

- replace the part.

E20 - short circuit of the NTC3 sensor.

Verify:

- NTC3 sensor connector;

- replace the part.

E23-E26 - errors on the main board.

Verify:

- replace the main board.

E32 - no subordinate (SALVE).

Verify:

- position of double-pole switches on individual units, bring them to ON state.

E33 - phase and neutral are incorrectly connected.

Verify:

- reconnect in the correct order.

E34 - error of the Reset button when pressed more than 7 times within 30 minutes.

Verify:

- wait 40 minutes for the error to disappear;

- replace the sub-board.

E35 - failure of the pressure switch.

Verify:

- check the water flow in each circuit, bring it to the rate of 2 m3 / h;

- replace with a new part with a setting of 500 l / h.

E36 - error on the slave board.

Verify:

- change the subordinate board.

E37 - crash when detecting fire.

Verify:

- clean or replace the electrodes.

E38 - short circuit of the smoke sensor.

Verify:

- replace the element.

E39 - no contact with the smoke sensor.

Verify:

- smoke sensor connector;

- replace the part.

E40 - 50 Hz error.

Verify:

- frequency in the electric line;

- connect a voltage stabilizer.

E41 - error on the slave board.

Verify:

- change the subordinate board.

E42 - short circuit of the sensor on the supply pipe.

Verify:

- sensor connector on the supply pipe;

- replace the part.

E43 - there is no contact with the sensor on the supply pipe.

Verify:

- sensor connector on the supply pipe;

- replace the part.

E44 - short circuit of the sensor on the return pipe.

Verify:

- sensor connector on the return pipe;

- replace the part.

E45 - there is no contact with the sensor on the return pipe.

Verify:

- sensor connector on the return pipe;

- replace the part.

E46 - overheating of the sensor on the supply pipe.

Verify:

- measure the water flow in each circuit;

- bring the flow rate to the rate of 2m3.

E47 - overheating of the sensor on the return pipe.

Verify:

- measure the water flow in each circuit;

- bring the flow rate to the rate of 2m3.

E48 - overheating of the smoke sensor.

Verify:

- measure the water flow in each circuit;

- clean the heat exchangers from 2 sides.

Sometimes there are situations when errors are not shown on the display of the Beretta gas boiler, but other symptoms of equipment malfunction appear.

These signs include the appearance of gas or burning odors in the room with the boiler, the delayed operation of the boiler burner, as well as a noticeable difference between the heating of the boiler and the temperature of the batteries. These malfunctions should be treated with as much attention as the codes on the display.

What do the indicator signals mean?

In some models of Beretta gas boilers, for example, Beretta City, the appearance of malfunctions in the operation of the units can be judged by the signals of the red, yellow and green indicators.

The indicators are two or three LEDs located on the central panel that start blinking at different intensities when a fault occurs.

In some models of Beretta gas boilers, errors and malfunctions are indicated by light indicators located on the control panel.

A blinking green light can mean the following:

- 1 time / 3.5 sec - the equipment is switched to standby mode, the fire is extinguished;

- 1 time / 0.5 sec - the boiler is stopped due to a breakdown;

- 1 time / 0.1 sec - the unit is switched to the automatic control system;

- the indicator is on and does not blink - the boiler is working normally, the fire is on.

The Beretta City may stop on its own due to a breakdown in case of receiving a signal from the pressure and smoke exhaust sensors.

The boiler can stop working for 10 minutes, during which the correct parameters must be restored. During this time, the system will automatically scan. A detailed guide on how to check the readings of the sensors of the Beretta gas boiler should already be laid down in the self-diagnosis system.

The indicators on the panel of the Beretta boiler can give signals in different combinations and with different intensities. The type of light signal depends on what kind of error occurred during the operation of the unit

The red indicator turns on in the following cases:

- the indicator is on and does not blink - if, after the suspension, the operation of the boiler is not adjusted, the unit goes into emergency mode;

- indicator blinking - activation of the limit temperature sensor. Sometimes the error can be eliminated using the mode switch.

Simultaneous blinking of the red and green diodes occurs in the event of a breakdown of the NTC sensor.

The yellow indicator comes on and lights up continuously when the preheating of the coolant in the circuit is turned on.

If you are not confident in your abilities and knowledge, it is strongly recommended to invite a qualified technician to repair the Beretta gas boiler.

To eliminate all of the above-described problems with Beretta gas boilers, it is strongly recommended to use the services of the masters of authorized service centers and organizations with whom contract signed for the maintenance of gas units and the supply of blue fuel.

Independent intervention in the complex design of boilers can lead to even more serious damage, which will result in costly repairs and a long shutdown of the autonomous heating system.

Conclusions and useful video on the topic

To eliminate failures and errors during the operation of the Beretta gas boiler, you must understand the principle of its operation:

The video below will help to recognize the errors of Beretta boilers:

An example of identifying and eliminating a Beretta gas boiler error:

If your Beretta gas boiler began to give out this or that error, it is not recommended to let things go by themselves and delay with repairs or adjustments. But before contacting the gas workers, it would be nice for the owner of the equipment to figure out what the equipment error is.

Knowing the cause of the detected failure will help the owner find the best solution to the problem when communicating with the authorized service master.

Do you want to talk about how you independently determined the breakdown of a Beretta brand gas boiler using an indication or a code? Is there any useful information that may be useful to site visitors? Please leave comments in the block form below, ask questions, post photos on the topic of the article.