We are sure that you are not a fan of contingencies. And, for sure, you do not want to change a completely new boiler because of a problem that has not been resolved in time. Meanwhile, even the devices that work the first day have problems. In the article we wrote about the errors of Kiturami gas boilers and their codes. Read it. Even if you do not have heating equipment of this brand, it is better to learn more about it - you will understand whether it is worth buying it in the future.

You will learn how to recognize the errors of Kiturami boilers. Find out what causes them, besides the main reasons. For convenience, we have submitted their codes in ascending order. Immediately after them, other failures and malfunctions were indicated that do not have codes. Read the article and you will know how to proceed in the event of a malfunction.

Boiler errors are determined through codes. They are different for manufacturers. Combinations of numbers from 01 to 98 pop up on Kiturami devices. The decryptions are the same for all boilers of this brand that operate on gas. They can differ only because of the names of individual modules.

The content of the article:

-

Gas boilers Kiturami

- Error codes 01 - 08

- Error codes 14 - 98

- Problems in the operation of Kiturami boilers

- Conclusions and useful video on the topic

Gas boilers Kiturami

Kiturami has been making boilers since 1962 and produces up to 9,000 units daily. Kiturami manufactures appliances that run on gas, diesel fuel, solid pellets. Gas boilers are made for fuel according to GOST 5542-2014.

Most of the products of the South Korean manufacturer have a double-circuit structure, a closed combustion chamber and they are fully automated. The efficiency of the devices reaches 94%.

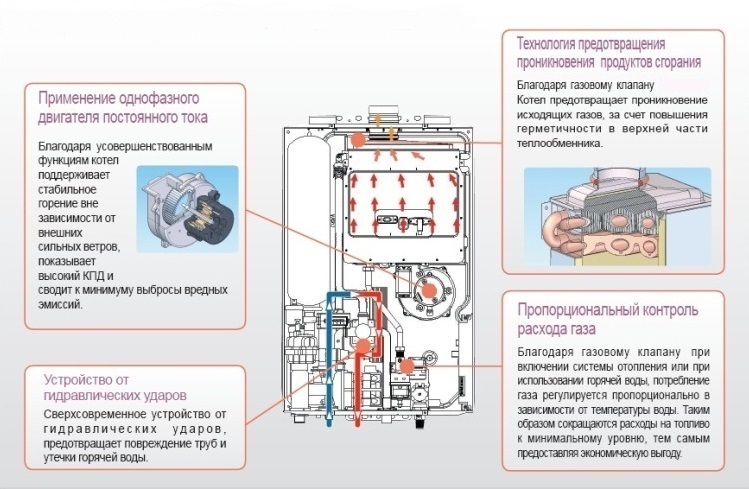

Kiturami uses low carbon technology, equips its boilers with a large number of fuses and sensors, makes compact and perfect internal designs

Popular models of Kiturami gas boilers:

- World Plus;

- Eco Condensing;

- TGB;

- KSG;

- World Alpha;

- Twin Alpha;

- World 3000;

- World 5000.

The power of Kiturami boilers reaches 465 kW, and for wall-mounted models it is in the range of 13-35 kW. Their turbocyclone burners operate at low pressure - about 30 mm air column. Each type of fuel has its own burner models that are capable of operating on the same boiler.

Kiturami appliances have protection against freezing and blowing out of the chimney. The heat exchangers in World Plus units maintain their performance over long periods of hard water use.

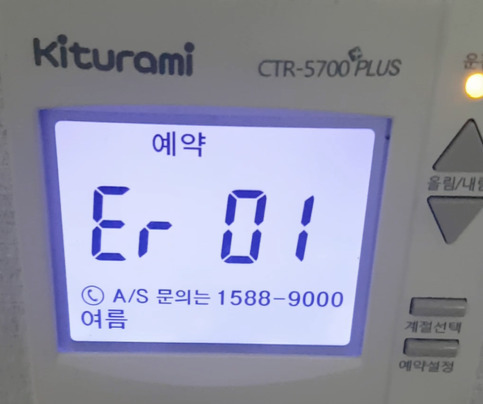

Gas boilers Kiturami serve up to 15 years and more, much depends on the conditions of use. The devices give errors with simple numbering - from 01 or from Er 01. Read about them to quickly troubleshoot problems and keep your device running.

Error codes 01 - 08

Errors from 01 to 03 indicate that the control system does not see the flame or has blocked the ignition - before or after starting.

Errors 01, 02 and 03 often appear due to a closed valve - open it and restart the device, at the same time check the boiler air supply

Code 01 - no flame. Follow the steps from the list, and if nothing changes, move on to the points:

- Open the gas supply valve to the maximum.

- Bleed air from the heating system.

- Inspect grounding. The wire may have lost its integrity, or it has been routed incorrectly. Re-ground the ground to a depth of 30 cm or more.

- Compare the gas pressure in the boiler with the indicator in the instructions. In case of discrepancy, call the gas workers.

- Check the integrity of the ignition cable and its power supply.

- Remove soot and dirt from the boiler burner.

- Also clean the ignition and control electrodes. Soot and carbon deposits collect on them. Set the electrodes in the correct position according to the instructions if the inclination has changed. Check if they work at all.

- Check that the gas valve and the photocell of the flame detection system are working. Swap items for new ones as needed.

- Check the PCB, connections and wires that fit. Replace if necessary.

Code 02 - false flame or its defect. Check and, if necessary, replace the flame detection photocell. Replace the board if it is broken and beyond repair.

Check it for oxidation, open circuit, short circuit. The burner nozzles could contaminate the electrodes. Clean them and put them in the correct position.

Code 03 - the flame appears and disappears for a short time. Ring the flame sensor and replace the faulty appliance. Check the pressure on the pressure gauge. Contact the gas service if the reading is outside the normal range.

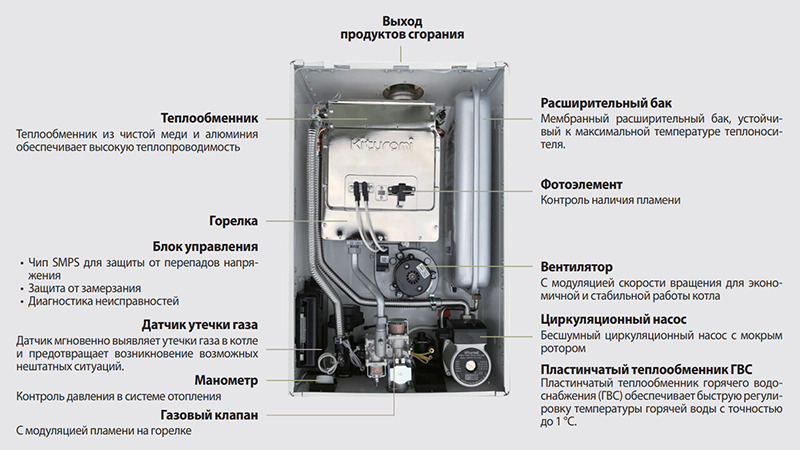

The structure of the Kiturami boiler with a flame sensor (photocell) of the flame control system, a pressure gauge in the lower left corner and a gas valve

Ventilation may be the problem. Open windows and doors, inspect the built-in ventilation ducts of the room. The error remains - check the external condition of the boiler fan and determine the resistance with a multimeter. The device could break. Look also into the chimney and take away all the dirt.

Code 04 - the temperature sensor of the heating element is not working properly. Inspect the wires that fit the sensor. Connect the broken wires and strip the oxidized contacts. Call the sensor for an open or short circuit. Examine the control board. In which case, contact the service where they are engaged in professional repair of Kiturami brand gas boilers - they are repaired in many services in the cities of Russia. Replace these assemblies as needed.

Code 05 - breakdown of the overheating sensor. Ring the seismic sensor, if your boiler has one. Replace as needed, but do not remove. Also inspect the overheating indicator itself. Determine the pressure in the system and add water if the reading drops. Take a look at the heat exchanger. If there is excess limescale, clean the assembly.

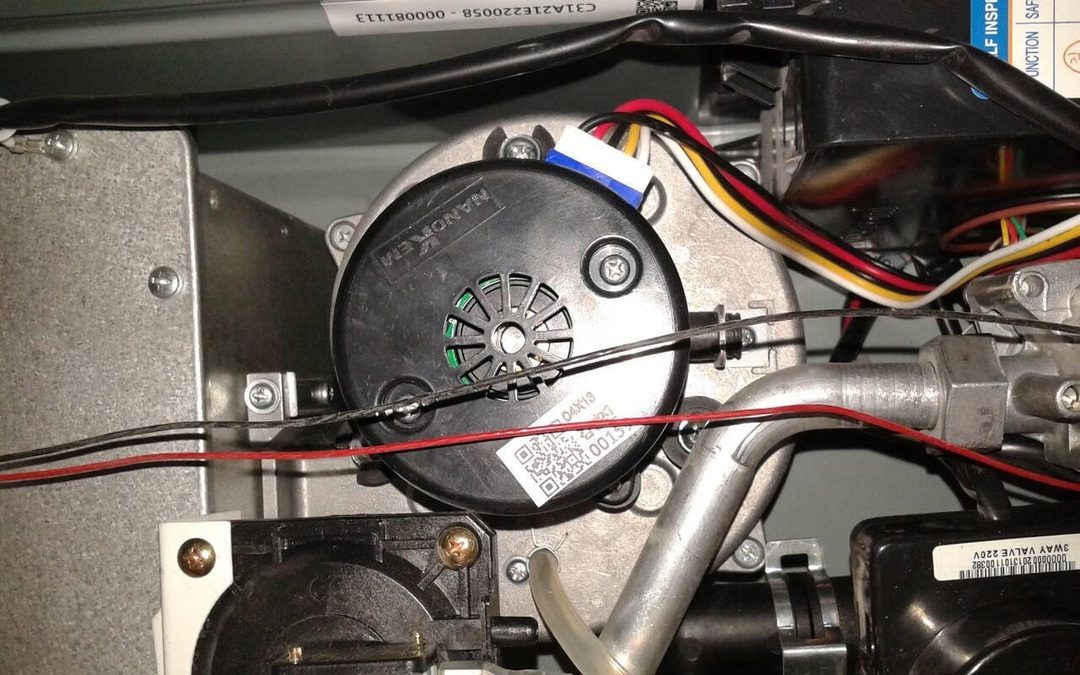

Code 06 - fan failure - it is not possible to determine its speed.

Fan for gas boiler Kiturami: the device supplies air to the combustion chamber, removes flue gases and other combustion products

To fix the error, you need to take seven steps:

- Examine the wires that lead to the fan. Clean if oxidized. Recover broken contacts.

- Assess the condition of the fan blades. If you notice any wear and tear, buy a new device.

- If the differential relay connections become sticky (also after loosening), replace the unit.

- Make sure the mains voltage matches the correct voltage. If not, install a transformer and uninterruptible power supply.

- Free the chimney from all strangers.

- Inspect the rotary fan assembly.

- Check the Hall sensor.

Replace all unusable parts.

Code 07 - problems with the chimney. The likely cause is the fan / blower speed is higher or lower than normal. Inspect the unit, remove foreign objects. At the same time clean the chimney from dirt and condensation.

The error pops up due to gusts of wind. If the problem occurs frequently, you will have to change the pipe pattern. You need to design taking into account the wind rose.

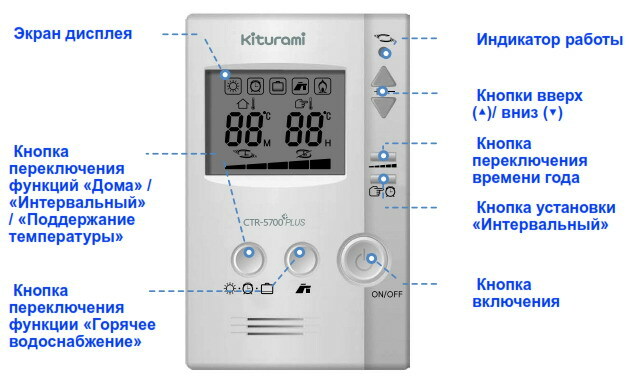

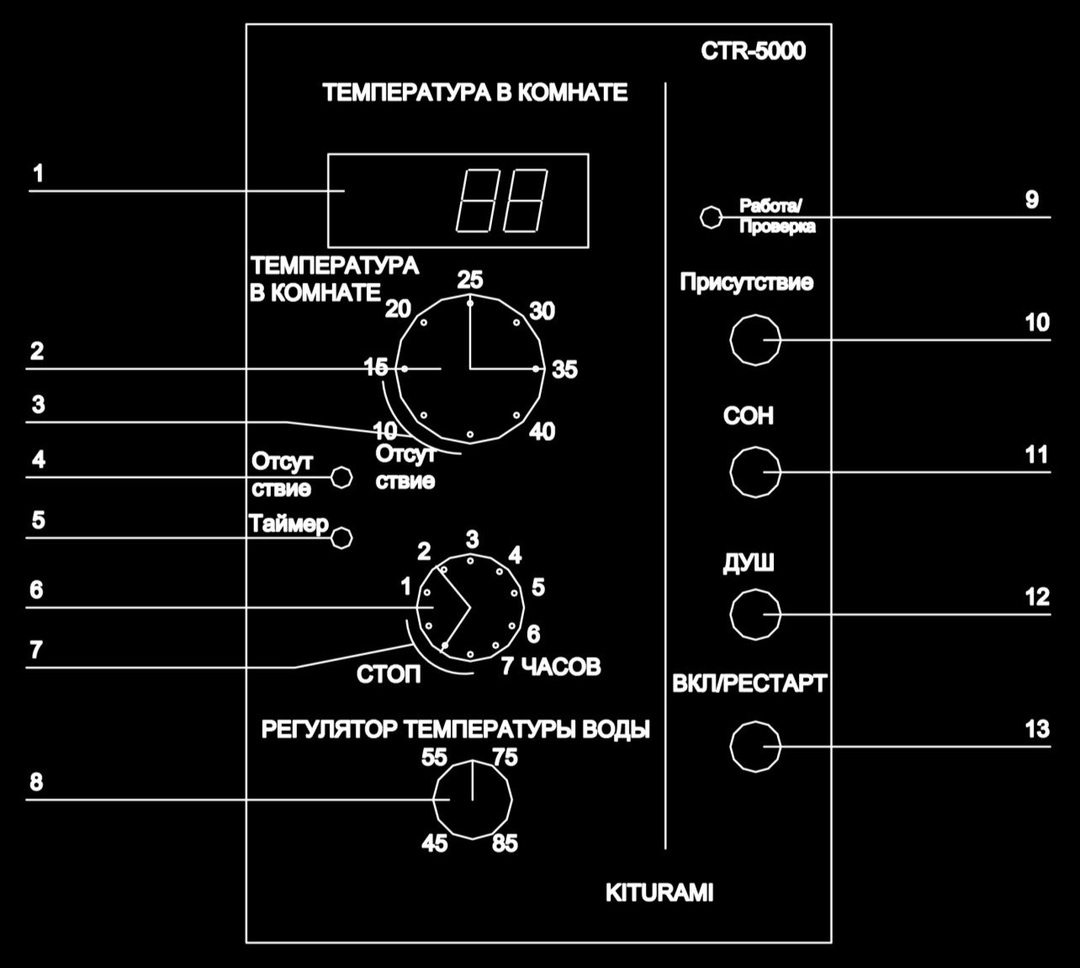

Many models of Kiturami boilers come with CTR remote thermostats, which make it easier to control the room temperature and allow you to set the operating time.

Code 08 - problem with the room temperature controller. The error appears when communication with the boiler control unit is broken. Code 08 will also pop up if the length of the regulator wire exceeds 10 meters. Thermostat cables are sometimes affected by telephone and high-voltage wires.

First of all, turn off the regulator and check the boiler operation. If all is well, first try to find another place for the thermostat and turn it on again. Re-route the temperature sensor cable and correctly if nothing has changed. Avoid placing in pipes under the floor.

Error codes 14 - 98

Let's start with similar errors - 14 and 34.

Code 14 - malfunction of the hot water outlet temperature meter. Look for a problem in the sensor itself and its wire.

Code 34 - an error of the same plan regarding the hot water inlet temperature sensor.

After the failure of the DHW sensor (hot water supply), the boiler will continue to heat the house, and regulation and maintenance of the temperature of the running water becomes impossible

Code 95 - indicates low boiler pressure / heating system, i.e. the lack of coolant (usually water).

Proceed like this:

- See if there is water in the boiler and what is the pressure in the heating circuit.

- Check and clean filters if necessary.

- Look for leaks in heating pipes and radiators. Then - eliminate leaks in the expansion tank and heat exchanger.

- Take a look at the expansion tank diaphragm. Replace if stretched or too dirty.

- Add water to the normal pressure.

- Inspect and repair the air valve on the pipe that supplies the heating medium to the heating system.

Code 96 - the temperature indicator has worked. The temperature has risen above the permissible 92... 97 ° C. The boiler will operate in emergency mode until the temperature drops. When the error disappears, restart the device.

Eliminate the cause of the temperature jump:

- Flush the heat exchanger from scale.

- Check and replace if necessary circulation pump.

- Ring the thermostat. Buy a new one if repair is not possible.

- Do the same with the board.

Code 97 - possible leak of gas. Natural gas may have escaped near the burner. Stop the gas supply to the boiler and turn it off. Call emergency gas service. Error 97 may also appear from the fact that air has accumulated in the system.

Technologies used in Kiturami boilers to ensure tightness: protection against water hammer and penetration of flue gases in the upper part of the heat exchanger

Code 98 pops up at liquid fuel devices. Indicates an insufficient level of energy carrier in the fuel tank.

Problems in the operation of Kiturami boilers

Not all problems have their own code, so we will consider them separately.

Indicator is off "Network" - check the power supply in the socket and the fuse on the ignition transformer. If there is no voltage in the mains, call an electrician, if there is, call the service department.

The indicator on the insufficient amount of water is on on the control unit - there is no water in the device or the level is too low. Damage to the black boiler wire and the red sensor cable also causes the problem.

The room temperature sensor works fine, but the radiators are cold - the circulation pump does not accelerate the coolant through the pipes or does it too weakly. Inspect the shut-off parts on the heating pipes. Check the pump itself.

The light bulb came on "Overheat" - the heating system is not working properly. Check it out.

If the problem persists, do the following:

- Adjust the shut-off valves on the heating pipes.

- The strainer may need cleaning. Examine it.

- Check the circulation pump, repair or replace if necessary.

Lights up diode "Safety" - little or no gas enters the boiler burner. Inspect the valves and open them if necessary. The problem remains - call the gas workers.

Schematic display of a room remote thermostat: 5 main modes were included in it, including presence, absence, shower, sleep, water heating control

The pump has been running for too long. The water temperature indicator on the control unit is constantly on - the heating system is not working properly or there are air jams in it. Let the air out.

The boiler began to heat up longer - look for a problem with the gas pressure and the condition of the filters.

The burner vibrates when switched on - the size of the chimney is not enough for the normal removal of gases.

The efficiency of the device in terms of hot water supply and heating has decreased - bad water or dirt from the heating system gets into the boiler. Chemical treatment of the circuits and heat exchanger will help.

Conclusions and useful video on the topic

Details on fixing the control unit after error 06:

Maintenance of the Kiturami boiler by gas workers:

You have read about the malfunctions in the Kiturami gas boilers and their symbols. Most of the errors indicate a temporary failure without risking the entire device, but be aware that the device may not work for several hours or days.

Fix any problem step by step. Keep an eye on the pressure in the device and heating system, mains voltage, external conditions. Avoid gas or water leaks. Eliminate them as soon as possible. Do not touch the gas lines inside the boiler and those that fit to it.

Write comments on the topic. Tell us about the most common mistakes on your boiler, its brand. Write down if you had to repair it and how many times. Are you satisfied with your technique? The contact form is located under the article.