The emergence three-layer pipes based on polyethylene, aluminum and polypropylene at one time it became a discovery for most fans to build with their own hands. Working with a rigid and at the same time flexible metal-plastic pipe was much more convenient than with steel or pure polypropylene.

But the real discovery was the fact that it was possible to bend the water pipes simply by hand, using a special spring for a metal-plastic pipe for this. Moreover, the bending quality was quite high.

The content of the article:

- When you need a spring

- How pipes are bent

- What gives the use of a spring

-

Spring types

- Internal springs

- External springs

- Calculation of the bend radius of a metal-plastic pipe

- Self-bending metal-plastic pipes with a spring

When you need a spring

The advantage of a metal-plastic pipe is a combination of relatively thin plastic plastic walls with rigid aluminum reinforcement. This means that with a small radial or longitudinal load, the product will behave like vinyl in the cold.

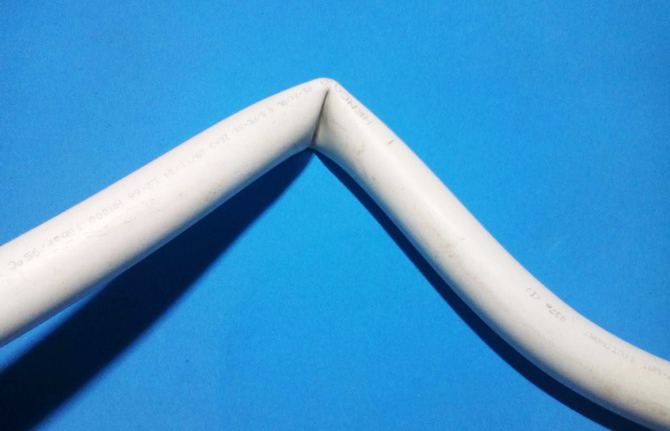

Up to a certain twist angle, it lends itself to uniform bending. As soon as the radius becomes less than a certain value, the metal-plastic pipe breaks with the formation of a "hinge" or mesentery.

You can try to align the workpiece, and there are special tricks for this, but only for short sections. If the problem arose with a long section of the heating system or underfloor heating circuit, then the situation can be corrected by installing two fittings at the break point.

The durability of the aluminum and polyethylene layers depends on how correctly the metal-plastic pipe is bent. If at least one of them was damaged, then the metal-plastic will inevitably fail.

How pipes are bent

There are several basic ways to properly bend a metal-plastic workpiece.

At home, three main ones are used:

- The pipe is bent using a hand or table pipe bender with a set of lodgements of different radius of curvature.

- Fast bending is performed using a conductor spring;

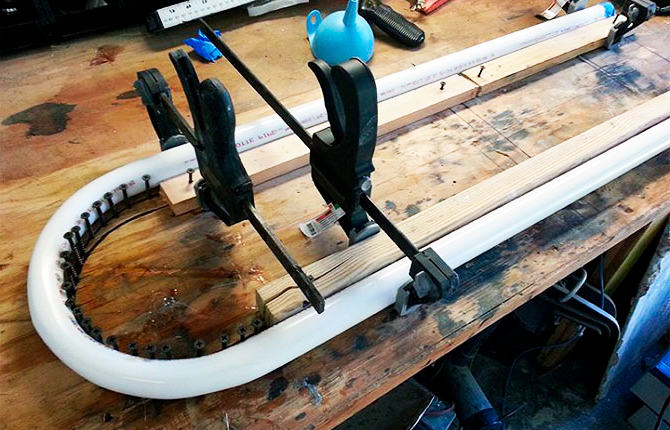

- Single bends can be done using a makeshift jig.

The highest bending quality is obtained when using a manual pipe bender, the lowest is obtained with semi-handicraft tools.

Any attempts to bend the pipe using a self-tapping template or a plywood conductor lead to peeling of polyethylene on the inner walls of the pipe. Even if the weld on the aluminum remains intact, there will still be no reliable protection of the metal from water.

There is no point in buying a pipe bender in order to bend a dozen radii. Therefore, the optimal solution would be spring for bending metal-plastic pipes, especially since its cost is an order of magnitude lower than that of a good quality hand tool.

What gives the use of a spring

In addition to an affordable price, the use of a spring jig has two advantages:

When bending the workpiece, the chrome-plated coils of the spring slide along the inner surface without scratching or damaging the thin layer of polyethylene.

The rigid base of the conductor spring does not allow the walls to deform in the transverse direction relative to the bending radius. The section will remain round, there will be no mesentery inside the metal-plastic pipe, which means that debris will not accumulate or rust will be deposited.

Another plus in using a spring is the ability to bend a pipe with a variable radius of curvature. It is performed only with hands and a spring. But only an experienced craftsman can make such a turn on a pipe bender.

Spring types

The only drawback of using a spring conductor is its "sharpening" for a certain diameter of a metal-plastic pipe.

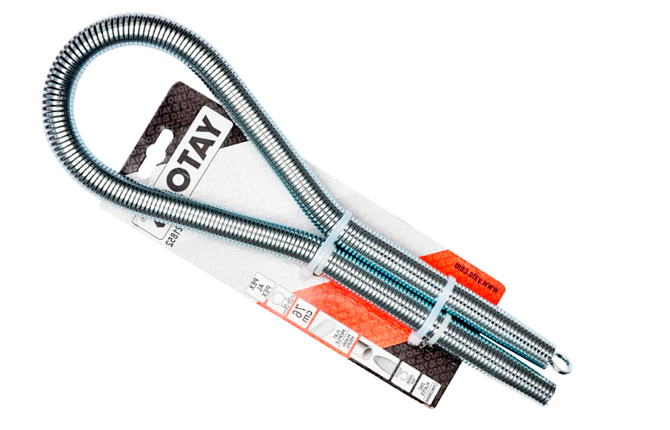

The size of the pipe blank is indicated on the package with the spring. Therefore, to assemble a water supply system or a "warm floor" system in an apartment, you have to buy spring conductors for several pipe diameters.

Often on sale you can find sets of two springs of different diameters, and the conductors look different. This is a kit for bending one reinforced plastic pipe, which includes one inner conductor spring and one outer spring for reinforced plastic pipes. Such sets are used to bend workpieces with a diameter of more than 25 mm. In other cases, you can use one spring conductor.

Springs can differ in wire profile. The cross-section of the wire base can be round or rectangular.

Internal springs

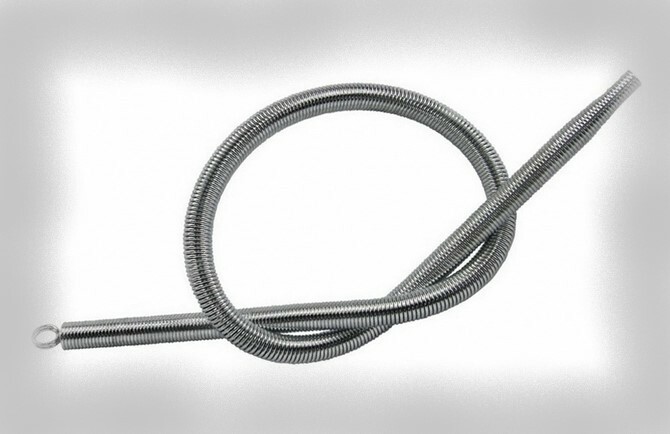

Flexible jig for bending a metal-plastic pipe can be easily distinguished by its characteristic wire cone at the end and the presence of a ring. Its outer diameter is 1-1.5 mm less than the inner size of the pipe billet. Therefore, the tapered end of the device helps to insert it inside and go through all the turns to the point of bending.

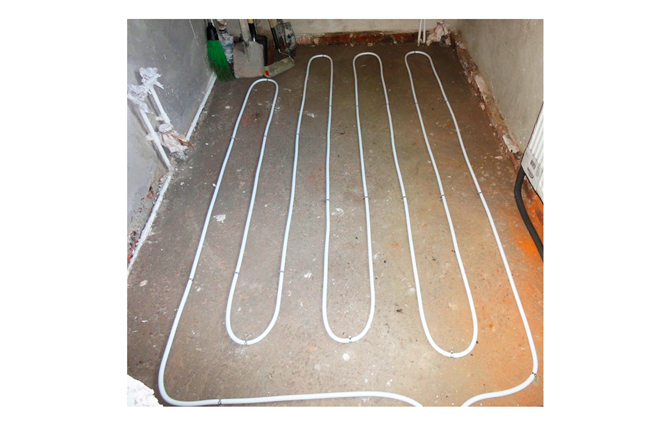

A cord is tied to the ring, with which you can drag the conductor to the place where the bend is made. The ring and the cone are considered indispensable when bending long pipelines, for example, if you need to lay a water-heated floor in one continuous segment.

External springs

This type of conductor spring is put on over the pipe blank, therefore one of the ends of the device is made in the form of a bell.

Models designed for bending small-diameter workpieces have rings at the ends, bent at an angle of 90O to the workpiece axis.

They serve to securely hold the spring with your hands when performing bending. Outdoor models are considered safer and more comfortable to use. The scrap rate is several times lower than when using internal conductors.

Calculation of the bend radius of a metal-plastic pipe

There is a conditional formula for calculating the minimum allowable radius of rotation of the workpiece body when bending in a cold state. For bending by hand, the radius R must be not less than the product of the outer diameter of the metal-plastic workpiece by a factor of 5. For example, for a 20 mm pipe, the bending radius must be at least 100 mm.

This means that a pipe billet bent by hand to a horseshoe or semicircle will have a distance between the ends equal to 200 mm.

When using a spring, the bending radius is taken equal to 3.5 diameters of the workpiece.

Self-bending metal-plastic pipes with a spring

There is a well-established opinion that pipe billets made of metal-plastic before bending need to be heated with a hairdryer to 80-90 OWITH. It is believed that the heated outer polypropylene and inner polyethylene layers become more plastic, easier to deform when bending.

In practice, heating the workpieces is recommended only if the work is done by hand, at temperatures below +5 OWITH. Otherwise, heating can damage the XLPE inner layer.

The bending process is as follows:

- Insert the conductor spring into the tube blank. If several bends are planned on a relatively short section of the workpiece, 10-15 drops of glycerin can be added inside. For long stretches, it is best to use a non-lubricated external spring.

- With the help of a cord or rail, the jig is pushed into the bending zone. For workpieces longer than one meter, the holes have to be closed with foam tampons so that the spring does not move before starting work.

- Flexion is performed in short, gentle movements. The conditional ends of the bent section are wrapped with the hands of the hands, the thumbs rest against the center and the workpiece is bent.

If a bend with a small radius is required, then you will need to make a grip with your hands slightly more than the length of the bent section. Bending is usually done in 15-20 bending movements. It remains to slightly loosen the bend to pull the spring out by the cord. Then rinse with soapy water to remove any remaining glycerine grease.

Have you ever had to bend metal-plastic pipes yourself?

The spring for metal-plastic pipes is a convenient and easy-to-use tool. Anyone can learn to work with a conductor spring. Often, bending devices are made by hand.

Spring for bending plastic pipes: video

Have you ever had to make do-it-yourself spring conductors in practice? Share how successful the springs turned out, was it convenient to bend the metal-plastic pipe with a homemade device. Save the article in bookmarks so as not to lose useful information.