A revolving staircase is a structure, the steps of which are located at a certain angle to each other. Allows you to freely climb to the next level. It is used in conditions of limited space, saves living space.

The content of the article:

- Types of turning stairs

- Preparation of materials and tools

-

Step-by-step instructions for making a turntable

- Calculations, drawings and diagrams

- Making a kosour

- Step manufacturing

- Construction assembly

- Installation of balusters and railings

Types of turning stairs

An individual house, even two floors, requires the arrangement of a comfortable staircase complex. If the room allows, install the usual flight of stairs, without bends. But this requires an impressive area.

The device of the stairs with a turn makes it possible to place it not only in a small cottage, in the country, but also in public buildings with high traffic. You can organize the rotation of the structure at any angle - from 90 to 270 °.

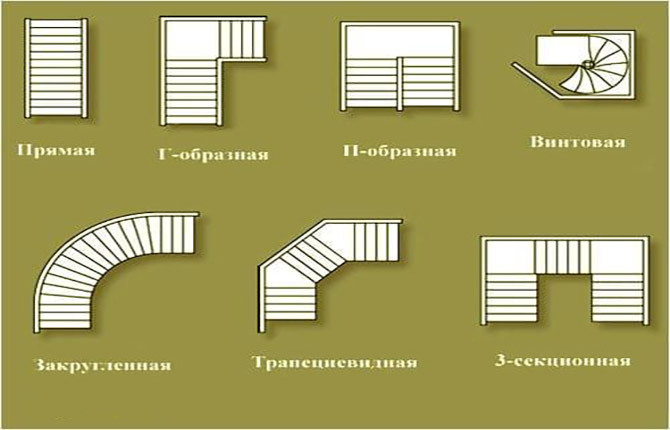

The variety of rotary stairs is due to the development of technologies for their manufacture. To determine which model is suitable in a particular situation, you need to know all their pros and cons, familiarize yourself with the types of construction:

- Marching. Consists of 2-3 marches with winders, which replace the landing, changing the direction of movement.

- screw. Consists of one rotary steps.

- Mixed. It has an L-shaped form. In this case, the upper part is marching, and the lower screw.

- U-shaped staircase. It looks like 2 straight marches and a turntable that turns it 180°.

According to the type of load-bearing elements, turntables are classified into monolithic, supported by a pole or console, as well as by stringers, bolts, bowstrings. As for the steps, they are straight, running, goose.

Along with all the advantages of such stairs, it should be noted the complexity in the design calculations. If a mistake is made, the module may come out inconvenient and unsafe. Another problem is some shortcomings of winders. Their inner side is narrow, it is inconvenient to place the foot. When moving on the outside of the stairs, one step is not enough. This is especially felt when moving down. But still, you can make a turning staircase to the second floor with your own hands.

Preparation of materials and tools

Swivel structures are made of wood, concrete and metal, as well as glass. A finished metal staircase can be bought or ordered according to the available dimensions. They are made from a profile pipe, channels, corners. Welding is used for installation. Welded areas are ground, treated against corrosion, painted. Steps can be wooden, metal or concrete.

Winder stairs

In the manufacture of a concrete structure, formwork is needed that repeats the shape of the turning staircase. It is assembled from timber, boards, plywood. Install reinforcement, pour concrete. After complete solidification, the auxiliary device is removed, the surface is polished.

Mosaic, tile, natural stone or wood are used as decoration. Concrete turntable is strong, durable, non-flammable. Silent when moving. The negative aspects are the arrangement of the formwork, the purchase of additional materials, the considerable weight of the structure, the need to equip the foundation.

The turning staircase made of wood is a tradition, comfort, reliability. A practical and durable complex will be made of oak, beech, ash. The pine material is no less beautiful, but inferior to the elite types of wood in terms of wear resistance. Not to be used in rooms with a high percentage of humidity. No flammability. The wood gradually dries out, creaks appear.

It is also not recommended to make a maple staircase. It is unstable to fluctuations in temperature and humidity, cracks under load.

Staircase with turntable

For the construction of stairs, you need to purchase a support and auxiliary beam of different sections, a cutting board for steps, fixing accessories, carpentry glue and epoxy resin. Fasteners must be of good quality with an anti-corrosion coating. Otherwise, due to the temperature difference between the materials, moisture will form. What will affect both wooden and metal surfaces.

To work, you need the following tools:

- hacksaw, electric jigsaw;

- Sander;

- screwdriver;

- chisel, hammer, mallet;

- tape measure, square, level.

The advantage of a wooden staircase is an attractive look, a relatively inexpensive material with many shades. If necessary, it is easy to update it - varnish, paint. The low density of wood reduces the load on the floor.

Spiral staircase

Pine is easy to adjust, correct inconsistencies. On the other hand, it is deformed, the knots fall out of their places, which becomes dangerous during operation. Requires impregnation from moisture and mold, protection against bark beetle.

Step-by-step instructions for making a turntable

Designing and installing stairs yourself is much more difficult than buying a ready-made kit. But there are a number of benefits. This is the purchase of inexpensive consumables, saving money at work. The opportunity to show imagination, develop your own project that matches the design of the house.

For a person who is little versed in repair and construction work, it is better to choose a completely wooden, as simple as possible design.

Algorithm for manufacturing a turntable:

- Type selection, measurements, amendments in accordance with the type.

- Execution of a sketch, calculation of the parameters of parts.

- Procurement of materials, fasteners, tools.

- Sawing, fitting, primary finishing of all elements.

- Assembly and installation of structures.

The choice depends on the purpose of the ladder, the frequency of its use. Before you do it, you should take into account some of the nuances.

Installation of a rotary spiral and mid-flight staircase saves space. But the screw design is a complex system, laborious to assemble. If the area allows, it is worth stopping at the option with two marches and a turntable.

Ladder on bolts (steel bolts)

The smaller the slope and the wider the steps, the easier the climb. This must be taken into account when there are children and elderly people in the house.

The strongest and most reliable system will be assembled on the bolts. Stairs experiencing constant heavy loads require the installation of a metal frame.

This is interesting!Metal staircase to the second floor.How to make a staircase to the second floor with your own hands.

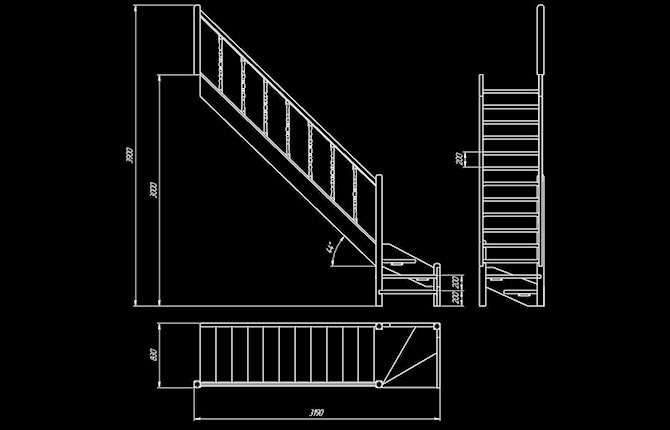

Calculations, drawings and diagrams

When making calculations, you can rely on general schemes, but it is necessary to take into account the specifics of a particular house, layout features, dimensions and other factors. Therefore, it will not work to make complex engineering calculations on your own, without a professional.

To draw up a drawing, you need to know the basic rules that apply to turning stairs:

- tilt angle - not steeper than 45 °;

- march width - at least 90 cm;

- step depth - 25 cm;

- riser height - 20 cm;

- railing height 90 cm.

All descendants must be the same height, except for the first and last. Different march widths are acceptable. When developing a project, you need to take into account the growth of the tallest resident in the house.

To make a drawing, display it on the floor plan, you need to take measurements and calculate the dimensions of the details of the future staircase:

- To determine the number of steps, the distance from the floor of the 1st floor to the floor of the 2nd (including overlap) is divided by their height.

- The dimensions of the march are calculated by multiplying the depth of the tread by the number of steps.

- If there are size restrictions, the depth of the steps is adjusted by dividing the length of the march by their number. Their ratio is adjusted so that the structure fits in the given height of the room.

- The entire area of \u200b\u200bthe structure is calculated by multiplying the width of the march by its length.

- To calculate the parameters of the support - beams, stringers, bowstrings - the Pythagorean theorem is used. Where the legs are the height of the flight of stairs and its horizontal projection onto the floor. The desired figure is the extraction of the square root of the hypotenuse from the sum of the squares of the legs.

- After calculations, all values are transferred to the drawing.

Dimensions should be observed, especially the ratio of height and depth of tread. Then the turntable will be comfortable and safe. Even with a detailed drawing, later you will need to fit the parts.

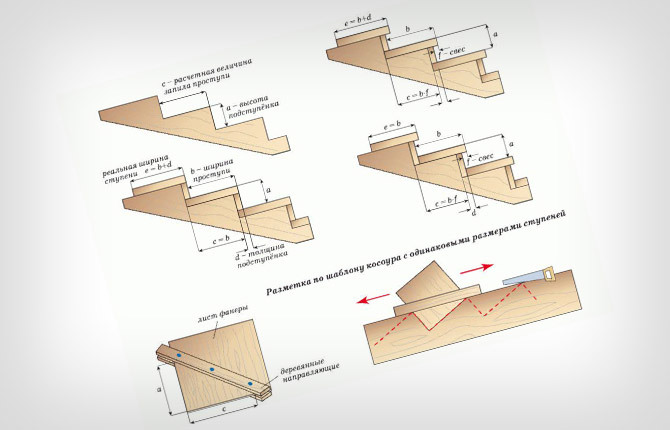

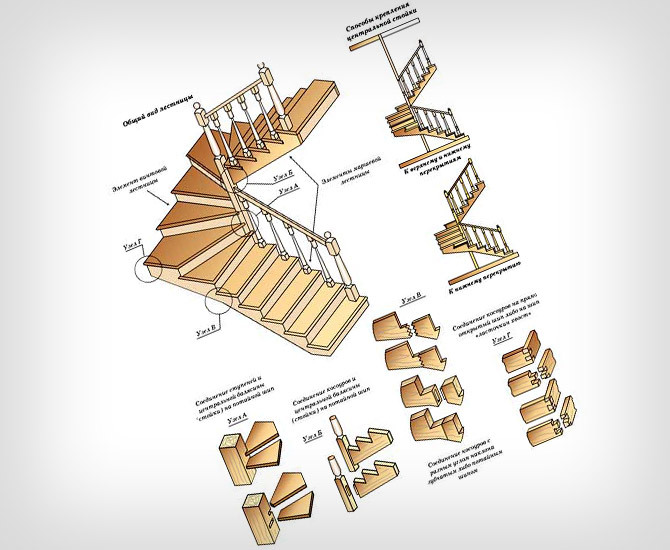

Making a kosour

A kosourny is called an inclined beam, on which boards of steps lie on top. If they are inserted into the grooves on the side, the method of fastening is called "bowstring". The beam is made of a board, 50 cm wide, with a section of at least 50 mm. Next, a stencil is made from improvised material. It marks the width and height of one step. With the help of a cliché, the entire kosour is marked. Saw with a hacksaw for wood or an electric jigsaw. The second beam is made according to the same principle.

When selecting wood, it is important that each element is cut evenly. The bumps will interfere with installation. All problem areas need to be cut off with a special tool, sanded with an emery cloth. Installation is carried out according to the level to prevent a difference in height.

Step manufacturing

The complexity of designing a turning staircase lies in the manufacture of winder steps. To make the construction convenient and safe, the following must be taken into account when calculating:

- the width of the tread from the inner edge is at least 10 cm, from the opposite - up to 40;

- the width in the direction of travel is the same as that of marchers - 20 and wider;

- the height of the risers should be the same, comfortable for all family members, taking into account a medium-sized step (60-64 cm);

- optimal angle of inclination.

So, for a 90 ° turning staircase, three cross-country descenders are enough. You will need a board 900x900 mm, 40 mm thick. It marks three lines coming out of one corner. The board is cut along the lines. Finished parts are customized in shape and length.

Construction assembly

The installation of U-shaped stairs with a 180° turn and L-shaped stairs by 90° is no different. All construction operations are carried out in the same way. Installation of the rotary structure is carried out in the following order:

- The platform is installed first. To assemble it, support columns from a bar are placed in the corners. The support is fastened with a board. For fasteners, metal dowels and anchors are used.

- A board with a thickness of 40-50 mm is cut out in accordance with the width and length of the site. Then laid on the finished frame.

- For the installation of rotary sections in the support, a groove is cut in height, slightly less than the thickness of the winder step. Thus, the inner swivel end will be securely fastened.

- The support is being finalized from the outside, securing the outer edge of the winder steps.

- Mount the stringers of the lower march.

- The assembly and fastening of risers, steps is performed from the bottom up.

- Similarly, the installation of the next march is carried out.

- Balusters and railings, if provided for by the project, are mounted last.

Balusters are installed on dowels. Their height and angle of inclination are marked by a stretched rope. The excess is cut off. The railing is fixed with self-tapping screws, sinking them. Holes are closed with putty.

Installation of balusters and railings

Self-manufacturing of such parts is questionable. They require special equipment to process them. Railings and balusters are located in plain sight, immediately attract attention. They must be of high quality. Therefore, it is more expedient to purchase ready-made elements.

The turntable is one of the most popular models. It will fit perfectly in a small room, for space saving and in terms of beauty. Made to order with a small platform or turning steps, it becomes a decorative decoration for the interior of both a private house and an office.

Tell us about your experience in terms of making a turntable yourself, leave a comment, share the article on social networks, and bookmark it.

What is the cost of stairs with a 90 degree turn?

The cost depends on the size, complexity of the project, installation methods, materials and components used. It is possible to accurately determine the cost of a turnkey construction only after the development of the project and the selection of all consumables.

How difficult is the installation of the turntable?

For professionals, it is not difficult. Installation technology depends on the type of construction. After all, each specific case has its own installation algorithm, and it takes into account both the design features and the installation location..