A drywall cabinet is one of the options to organize a large storage space in the room. You can buy it ready-made in a furniture store, order it to the required dimensions, do it yourself from plywood or other wooden flat materials. But all this is not cheap.

Drywall makes this piece of furniture inexpensive. In addition, there are several options for its finish, which allows you to choose one at your discretion.

The content of the article:

- Design Options

- Finding a suitable place to install the cabinet

- Sketches and drawings

- Stages of construction

- Preparation of tools and materials

- We markup

- Assembling the frame

- Plasterboard sheathing

- Finishing

Design Options

Regardless of what material the cabinet will be made of, all designs are divided into 2 types:

- Straight cabinet. This is the one that is installed along the wall. He can cover all or part of it with himself. But this is a rectilinear construction (exposed in a straight line).

- Corner cupboard. These are 2 rectilinear models connected at a right angle. Although the angle may not be right. Typically, these cabinets are installed in the corner of the room. This is not ideal for all rooms, because it takes up a lot of space.

These are 2 main categories, which include several groups. Two of them are the most common and frequently used:

- Built-in model, when a niche is used to install furniture. Often the pantry in an apartment or house is replaced with a closet.

- Closet, which differs from other types only in the door opening mechanism. It can be built-in, angular or straight.

Finding a suitable place to install the cabinet

Everyone decides for himself where the drywall cabinet will be installed. This applies to both the room and the place in it. For example, more often installation is carried out in the hallway. For this, a wall along the room stands out. A mirror is also installed here. A built-in rectilinear type cabinet is usually constructed.

If you need to organize storage space in the bedroom, then the corner option is suitable. Rectilinear also has a place here. Rarely built-in models are built in bedrooms.

Nevertheless, special attention must be paid to the installation site. After all, a drywall cabinet cannot be moved to another place, like a regular one bought in a store. Because it is a piece of furniture with fastening to building structures: floors, ceilings and walls. It is installed once and for many years.

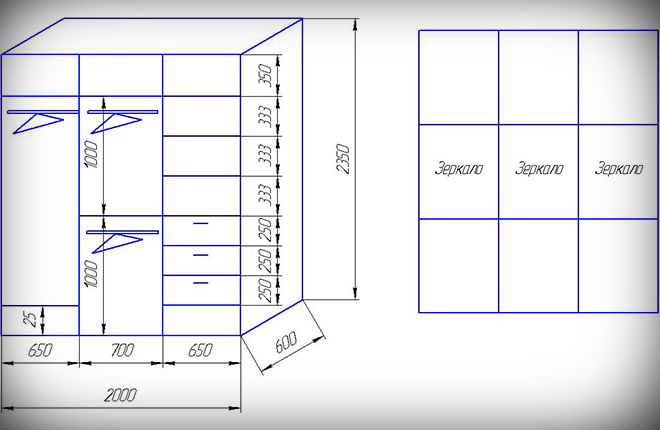

Sketches and drawings

Regardless of what type of cabinet will be built from drywall, it is necessary to draw a sketch on paper. This mainly concerns the number of shelves, doors, hinged rails and other things. Here we mean how many there will be, large or small, where they will be located.

The second is the dimensions. It all depends on the place where the cabinet will be installed. Its overall dimensions will be the main for the dimensions of the elements: shelves, niches and other things. But there are certain standards that fall into the design when determining the size of the cabinet and its elements. What you need to pay attention to:

- width and length of the drywall cabinet;

- distance to interior doors;

- how much free space in front of the furniture.

All 3 criteria will help you choose the type of door structures - swing or sliding. This is a serious question, it is impossible to dismiss it at the design stage. For example, in narrow hallways and corridors, it is better to mount compartment doors in which a cantilever bar is installed - across.

Next, decide what will be stored in the closet. For example, outerwear, shoes, bags and some utensils are stored in the hallway. In the bedroom - underwear, bedding, shirts, trousers, dresses and more.

Now you need to know exactly who will use the future drywall cabinet. For example, if the structure being constructed will be used by all family members, then it must be made large. If it is being built in a children's room, then large dimensions are useless here. But you need a lot of shelves.

For men, one or two shelves, as well as a long bar, are the best option. For women, the more shelves, the better.

About the mounting height of the rod:

- for coats - installation height 1.7-1.9 m;

- for trousers and shirts - 1.2-1.3 m;

- for short things, 2 rods are usually installed, one above the other, with a distance between them of 0.8-1.0 m.

You need to decide on the size of the shelves. Their number will depend on this. For example, if a drywall cabinet will be built in the hallway. Here are the recommended shelf heights:

- for shoes - no more than 20 cm;

- for bags - 35 cm;

- for hats - 20 cm;

- for small things: keys, brushes, shoe polish and so on - there are no standards and recommendations, everything is at the discretion of the owner of the apartment or house.

If a drywall cabinet is being built in the bedroom, then the shelves should be higher than described. The reason is simple - large things are stored in such a closet: bedding and towels. Therefore, the height here should not be less than 30 cm. And the depth of such furniture is significant - 60 cm. In the hallway, 40 cm will be enough.

Much depends on where this piece of furniture will be installed. The smaller the room, the smaller the wardrobe should be.

Stages of construction

Step-by-step instructions for making a drywall cabinet are several construction operations that go one after another:

- The location of the cabinet - you need to accurately determine it.

- Taking into account the dimensions of the selected place, a scale drawing is made with the exact dimensions of the entire structure and its elements.

- Taking into account the dimensions of the cabinet, the necessary building materials are purchased.

- Tools are being prepared.

- The future frame is marked, taking into account the dimensions according to the drawing.

- Installation of a frame made of metal profiles.

- Sheathing the frame structure with plasterboard.

- Primer, putty and finishing.

Preparation of tools and materials

Regardless of whether they build a drywall cabinet with their own hands or craftsmen do it, the materials and fasteners, as well as the tools, will be the same.

Materials and fasteners:

- wall drywall with a thickness of at least 12.5 mm;

- 2 types of metal profiles - rack and rail;

- self-tapping screws and plastic dowels to them for fastening profiles to walls, ceiling and floor;

- self-tapping bugs for attaching profiles to each other;

- self-tapping screws for attaching drywall to the erected frame;

- perforated paper tape or fiberglass tape;

- putty and primer;

- perforated corners made of plastic or galvanized steel for sealing the corners of drywall sheets joined on the frame.

Tools:

- drill with a drill;

- screwdriver;

- plumb;

- building level;

- drywall cutting tool: hacksaw or sharp construction knife;

- metal shears for cutting profiles;

- spatulas;

- roller or paint brush;

- ruler or rule, a simple pencil.

We markup

Here everything is strictly according to the drawing. From the wall at which the drywall cabinet will be assembled, the depth of the future piece of furniture is laid along the adjacent walls. This is best done near the ceiling. Now the 2 marked marks must be connected to each other by a line along the ceiling, using a rule and a simple pencil.

You can use a paint thread and beat off a colored line on the ceiling. Any method is chosen so that markings appear on the ceiling for the installation of a steel profile.

Further along the walls located opposite each other, a plumb line is lowered from the ceiling markings to the floor. It will indicate the installation locations of vertical profiles. Here you also need to leave a line. It remains only to connect the marks formed on the floor. It turns out a rectangle with sides along the ceiling and floor, two opposite walls.

Assembling the frame

The first is to cut segments from the guide profile. Their lengths are equal to the sides of the frame structure rectangle. Holes are drilled in them every 30-50 cm. Each segment is applied at its place of installation and through the holes made on the planes of building structures, marks are made with a simple pencil.

Profiles are set aside. According to the marks, holes are drilled for the dowels, where the latter are inserted. Then attach the profiles back and fix them with self-tapping screws using a screwdriver.

It is recommended to lay a special tape under each profile, which will dampen structural sounds. It is self-adhesive. You just need to remove the protective film from it and stick it to the reverse sides of the profiles. The tape will be between the latter and the planes of building structures.

The profiles must be laid so that the lines drawn on the walls, floor and ceiling are on the edge (front or back), but not in the middle.

Strictly according to the drawing, determine the installation locations of the rack profiles. Taking the dimensions from the drawing, transfer them to the assembled rectangular frame. The rack element is mounted strictly vertically, for which a plumb line is used. Therefore, it is necessary to apply the size of the installation site on a guide attached to the ceiling. And already from it, with a plumb line, determine the attachment point on the guide near the floor.

In this way, all vertical elements are exposed, which are attached to the guide bugs. In the same way, installation operations are carried out related to the installation of rack elements attached to the wall, in which the drywall cabinet is being built. Vertical racks are mounted on the wall, which are located strictly opposite the racks attached to the rectangular frame of the rails. They are attached to the wall in the same way as the guides - on self-tapping screws and dowels. Shock-absorbing tape is a must.

Vertical racks are connected in pairs along the floor and ceiling with the same rack elements. The result is a three-dimensional structure, the strength and rigidity of which must be increased by fastening the vertical racks together in pairs with intermediate elements. Their locations are the locations of the cabinet shelves. Strictly according to the drawing, these dimensions are transferred to the structure, where the trimmed rack profiles are mounted to the rack.

The same must be done with the sections that will divide the structure horizontally. For example, you should get something similar to the design in the photo below.

You can’t save on the construction of a drywall cabinet frame. The design must be strong, reliable, last a long time without creating problems. Therefore, the more jumpers between the main elements, the better.

Moreover, when working with metal profiles, there is always unused material. Therefore, it is better to put it on jumpers, especially in those places where there will be heavy loads. These are usually shelves, rod attachment points. The wider the shelf, the more jumpers must be installed.

Masters with extensive experience advise installing wooden bars inside the rack elements, which will increase the strength and bearing capacity of places under heavy loads.

Plasterboard sheathing

The most important step in sheathing is to properly cut drywall. Even the most accurate dimensions can create errors when laying cut sheets, because the frame is assembled along walls, ceiling and floor, which do not meet maximum evenness.

Somewhere deflections, bulges will be required. Even if small, but they will not let you stand at the installation site of the cut drywall piece.

How to cut drywall correctly:

- cut out a piece of drywall;

- applied to the area that needs to be covered with sheet material;

- identified inconsistencies;

- outlined them with a simple pencil;

- cut off protrusions or other irregularities;

- applied again at the place of installation;

- check if everything matches exactly.

Helpful Hints:

- drywall sheets are joined in the middle of the installed profiles;

- sheathing must begin to be carried out from the far wall;

- the frame is completely closed;

- self-tapping screws are screwed in every 10-15 cm;

- the distance of their screwing from the edge of the sheet is 1-2 cm;

- the cap of the fastener must be screwed in, sinking 0.5 cm into the drywall body.

The process of cutting drywall itself is simple, but it takes a little experience to understand the cutting technology. Cardboard is cut with a sharp knife, its tip deepens by a third the thickness of the drywall sheet. Sheet material is placed on the edge of the table along the cutting line. The hanging part must be pressed by hand. The sheet will break at the cut. It remains only to cut the cardboard from the opposite side. If the cut line turned out to be uneven, then it can be worked out using a drywall planer.

Finishing

The built-in drywall cabinet is almost ready. It is necessary to seal the joints and seams between the sheets of drywall, level the entire surface and choose a finishing method.

The joints are filled with putty using a spatula. It is necessary to cover with a mixture and the places where the screws are screwed. While the solution is not dry, a mounting tape is laid on it. It must be firmly applied so that the putty mixture comes out through the holes. The purpose of the tape is the reinforcing frame of the seam. On top of another layer of putty. It is recommended to treat the surfaces of the joints with a primer before puttying. After it dries, putty mixture is applied.

Any wardrobe and drywall, including many corners. These are vulnerabilities that quickly become unattractive. Therefore, they are strengthened. For drywall, special perforated corners are used, made either from plastic or galvanized steel.

The corner of the structure is treated with putty. Immediately, until it dries, a corner is applied and another putty layer is applied on top.

Further, all drywall surfaces are treated with a primer liquid - inside, outside. Used paint roller, brush. The primer is applied in at least 2 layers - the second after the first has completely dried. Further, all planes are puttied. After drying, the surfaces are treated with fine-grained sandpaper. The purpose of the operation is to remove particles of protruding leveling material, trowel marks and small irregularities.

Usually drywall is painted with a water-based emulsion. But no one forbids covering it with wallpaper. If a plasterboard cabinet was erected in a bathroom or on a balcony, then you can finish it with ceramic tiles or plastic panels.

With the last two options, you can save money, because under the tile it makes no sense to carry out leveling operations associated with applying putty. Ceramic tiles and plastic panels are themselves leveling materials. The only thing is that drywall must be well primed under the tile.

But more often a drywall cabinet is painted. In this case, the water emulsion is applied in 2 or 3 layers. Subsequent necessarily after complete drying of the previous one. And if the first layer is applied vertically, then the second horizontally, and the third again vertically. This is if a roller and brush are used for painting. If a spray gun, then there are no requirements for the direction of paint application.

The last thing in the construction of a drywall cabinet is the installation of various elements: doors, rod, hooks, mirrors, and more.

A consistent action plan simplifies the construction of any drywall structure. It is practically unchanged, so this step-by-step instruction can be transferred to any drywall construction - wall, ceiling, niche, shelves, etc.

Whoever created a cabinet or other piece of drywall furniture with his own hands - respond. Write in the comments about your experience. What exactly did you collect, how did it go, were there any difficulties?