Self-manufacturing of furniture and beds, including, provides many advantages: the exact required dimensions, high strength, long service life. There are a lot of materials that are used to build a bed. But it's easier to work with lumber. One option is a bed made of timber.

The content of the article:

- Possible Implementations

-

Step-by-step instruction

- Preparatory stage

- Element manufacturing

- Step by step assembly

- Finishes and decor options

Possible Implementations

Option 3. The classification is based on the height of the structure:

- Outdoor, he's a podium. This is a bed without legs. The supporting structure lies on the floor base and there is no free space under it. This is the easiest option for implementing a bed made of timber in terms of manufacturing and cash costs.

- Standard model, the height of which is 50-60 cm.

- High. Its height is 80 cm. Typically, such structures are erected in small rooms where additional storage space is required. Under the bed there is a lot of free space where you can build drawers on rails or on wheels.

It is impossible to take these 3 models as a basis. These are just standards used by furniture makers. You can choose any height. In this regard, there are no restrictions, only common sense.

As for the design, the design can be standard, that is, with a headboard and footboard - these are 2 sidewalls. It may be without them or without a foot. If a bed is being built for a children's room, then the variations on the design theme increase significantly. For example, a model with an attic made of timber or bunk bed. The latter can be assembled with an ordinary staircase or a side staircase, which is made in the form of a chest of drawers.

But one thing must be taken into account. A bed made of timber is a massive construction, so it is better not to install it in small rooms. In addition, it does not fit into all styles of premises.

A few tips from professional designers:

- If the country style is used in the house, then it is better to use not a rectangular bar, but a log for making a bed.

- If this is a loft style, then it is better to use raw timber. Furniture must be rough. Ideally, if the room has a brick wall.

- In the classics, timber can also be used, but it must be beaten with thin and graceful lines. For example, a headboard made of bent boards with an ornament. Here the standard model is selected.

- Provence is also no stranger to a bed made of timber. Only it will need to be painted white and covered with a bright blanket on top.

- The beam does not fit into the Art Nouveau style. This direction has the main distinguishing features - smoothness, roundness, fluidity and flexibility. A straight beam cannot provide this.

Step-by-step instruction

The entire assembly process must be divided into 2 stages:

- Preparation;

- assembly.

At the first stage, lumber is harvested, which is calculated taking into account the size of the bed. This is where trimming and preparation of the timber is carried out.

At the second stage, parts of the bed are assembled, which are then connected into a single structure. Next, the issue of finishing is already being decided.

Preparatory stage

You need to sketch a drawing of the bed and, in accordance with the number of elements, purchase a beam.

Master furniture makers recommend making a bed from 3 species: oak, beech or cedar. All three are highly durable, which guarantees a long service life of a piece of bedroom furniture.

Timber from these species is not cheap, therefore, if the budget is limited, then you can use lumber from other trees: pine, larch, ash, and so on.

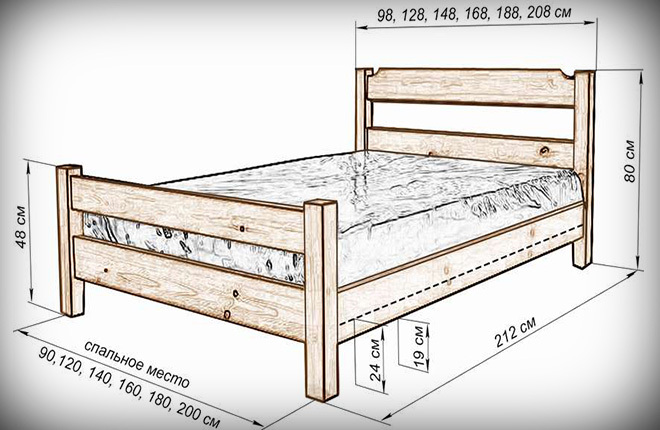

Drawing of a bed from a bar

You need to start by determining the installation location. This is important in the sense that many people want a large bed, but there is no place in the room for it. Therefore, it is necessary to measure the area of \u200b\u200bthe room with the area of \u200b\u200bthe bed. Because you need free space to move, install other pieces of furniture, such as bedside tables, wardrobe and others.

Next, you need to draw a design as a whole and in detail on a blank sheet of paper. It is important to draw every detail, indicate the dimensions. This will simplify trimming to the required dimensions and further assembly into nodes and into a single structure itself.

If a bed made of timber is made by hand for the first time, then problems may arise with the creation of a drawing. While seemingly simple, this is not so easy to do. Especially draw and accurately set the dimensions of each part. Therefore, you can take the finished drawing as a basis. For example, as in the photo below.

What tools and materials are needed

Here you will need a standard set of carpentry tools:

- a hacksaw, if there is a circular saw, then it is better;

- drill;

- screwdriver;

- joiner's square;

- ruler, tape measure and a simple pencil.

From the materials of timber and boards, as well as fastening materials:

- self-tapping screws;

- steel perforated corners for connecting parts;

- sandpaper;

- putty for wood;

- colorless varnish, stain - if needed.

The main structural element is a beam. You can buy a section of 100x100 or 150x150 mm. Boards will also be needed, but only for the manufacture of the headboard and lattice elements for the base under the mattress. Here you need boards with a thickness of 30-40 mm. The lattice must be laid on supports, which will themselves be attached to the internal planes of the frame. They can be made from a bar with a section of 50x50 mm.

Element manufacturing

All elements of a bed from a bar are made strictly according to the drawing. Some of them will be paired, which simplifies their markup. You can’t make a mistake here, especially if the size is applied less than the required indicator. You can build up a beam, but in the case of a bed, this is not necessary.

frame

This bed assembly is basic. Its shape is a rectangle. Therefore, it has paired sides with the same dimensions. They are applied to the timber and cut with a hacksaw. After the ends of the cut are processed to maximum accuracy. That's why cutting with a circular saw is better than a hand saw. The cut is straight at a 90º angle. You don't need to work it out.

Now about connecting all 4 beams into a single structure. Here are a few methods on how to do this to ensure high strength and reliability. The most difficult thing is to make gashes of the ends of the elements to be joined. It can be washed down in half or dovetail. Next, 2 beams are connected using an adhesive composition.

Another not the easiest option to make a frame is to use wooden pins or dowels. It is necessary to cut the ends to be joined in half and drill through holes in them, where a wooden pin is inserted. In this case, both the pin itself and the contacting planes are treated with glue.

The simplest option, which is suitable for those who assemble a bed from a bar for the first time, is to use steel perforated corners and self-tapping screws. No washed down, glue, although the latter can be used to enhance the fastening of elements.

It is done like this:

- docked 2 beams:

- laid a steel perforated corner in the corner of the connection;

- tightened the last self-tapping screws with a length of at least 70 mm.

Here it is important to precisely dock 2 elements at a right angle. Therefore, it is recommended that the entire assembly process be carried out on a flat area. Abutting planes can be coated with adhesive. Although this is optional.

There is one method on how to properly assemble a frame structure in terms of right angles. To do this, the beams are laid on the sides of the rectangle and connect adjacent to each other with one self-tapping screw. Here it is necessary that the structure does not part.

Now we need to measure the diagonals of the rectangle. If they are the same, you can proceed to install the mounting brackets and fasten them with self-tapping screws. If the lengths of the diagonals are different, then the rectangle will have to be aligned by shifting the corners.

For example, for a floor model, a rectangle made of timber is a ready-made base. You can subsequently lay a lattice under the mattress on it, and, in principle, the bed is ready for use. It turns out a sofa, and if you dock a headboard to it, you will already get a full-fledged bed.

From this floor model, you can make a structure with legs. Raise it off the floor. And there are many options on how to do it right:

- Cut 4 pieces from a 100x100 mm timber, 20 cm long.

- Install them vertically at the corners of the rectangle, attach to it with perforated tape and self-tapping screws.

- Lay them not vertically, but horizontally under the short or long side of the bed structure. 100 mm - the height is small. You can increase it by laying on top of each other not one beam, but 2-3.

A frame is formed in a different way, in which the supporting legs are the basis. Their length depends on the chosen design. Because the legs usually additionally serve as the basis for the formation of the headboard and footboard. If the latter are present in the design, then the length of the racks is selected taking into account their height. They will either be the same, or 2 at the head will be longer than 2 at the foot.

The assembly of such a frame is not a connection between the beams that form a rectangle. This is their fixation to vertical supports - legs. Although there is an option when a rectangle is first assembled, and then support posts are attached to it. Their location is inside the corners of the rectangular frame.

The overall assembly of the bed is complicated by the fact that the legs will take some space inside the frame structure. Therefore, the lattice of the lounger will not be rectangular, but with cutouts for the corners under the legs. And although this is also easy to do, this option is not always chosen when a bed is made from a bar with your own hands.

Since the beds are single and double, there are some points that relate to the latter. Their frame-frame is assembled in the same way - in a rectangle. But to increase the rigidity and stability of the double bed, another beam is added in the middle. It is laid along, attaching to the transverse sidewalls with the same corners and self-tapping screws. The intermediate beam is attached to them from 2 sides. This will ensure maximum reliability, because the middle of the bed is often subjected to heavy loads.

Base

Under the base of the bed is meant the lattice on which the mattress is laid. Usually it is made from wooden boards. This can be a separate structure, then bars with a section of 50x50 mm are added. They make a rectangular frame.

It should be smaller than the bed frame. In this case, the external dimensions of the first should be slightly smaller than the internal dimensions of the second. The reason is so that the first can fit inside the second.

In order for the grate to be laid inside the bed frame, it is necessary to fix several bars of 50x50 mm with a length of 20-30 cm every 10 cm on the inner surfaces of long beams. You can use not segments, but a solid long bar. Its location is 5 cm from the top edge of the bed frame beam. In fact, these are the shelves on which the grate will fit.

How to build a grid.

- A frame is assembled from a bar 50x50 mm in the form of a rectangle. The elements are connected to each other with self-tapping screws.

- Boards 25-30 mm thick and 100 mm wide are mounted across the assembled rectangle. The distance between them is 100-250 mm.

- Connection method - self-tapping screws.

There is a version of the base, which will be non-removable. To do this, the prepared boards for the lattice are fastened with self-tapping screws to the shelves on the frame-frame. This simplifies the layout of the bed and its assembly.

The downside of this design is that if you need to disassemble it, you will have to remove each board, number it so that the sequence of connections is not disturbed during assembly. Although this is not so important, but experience says that it is better to lay the board in its place.

headboard

Before you make a bed out of timber, you need to accurately imagine the final product. Will it be with a headboard or not. On the one hand, this detail of the bed is not the most important. But it is she who makes the bed so. At the same time, the headboard is decorative. The more beautiful and unusual this detail, the more beautiful and unusual the bed itself.

The manufacture of the headboard is based on fantasy. There are a huge number of variations. And the simplest is 2 boards located across. There may or may not be a gap between them. Another simple option is narrow boards installed vertically. They can be processed or even unpolished.

The most common headboard assembly option is with fastening to the legs. The frame is assembled on legs, 2 of which are long. Their height is determined by the tastes of the owner of the house. Headboard elements are attached to them, for example, perpendicular boards.

The headboard can be introduced into the construction of a bed made of timber as a separate element, but already finished. Or a frame-frame is assembled separately on racks, decorative elements are mounted to the latter.

If the bed is floor, then the headboard can be attached to the frame as a separate finished element.

Step by step assembly

The instructions for assembling a bed from a bar are simple. But here one thing must be taken into account, from which individual parts and blocks it will be assembled. It is possible to assemble a bed from separate parts in the form of beams and boards of different sections, using each part in sequence. You can assemble the parts separately, and then combine them into a common design.

It cannot be said that one option is easier than the other. But in terms of preparation, the second method is better. To do this, prepare the details of each part separately. Of these, this part is collected and set aside. It is already ready, so its parts will not interfere with the assembly of other parts.

Ready-made parts of the bed are assembled into one design:

- It is assembled from 4 frame-frame beams, which are pre-cut to the required length dimensions.

- A lattice is assembled from boards and bars (also pre-prepared).

- The last part is the headboard.

- If the frame is assembled on legs, then the latter must also be cut to the required size.

- All parts are assembled into one structure: the frame to the legs, to the frame bars in the form of shelves, the headboard is mounted, the lattice under the mattress is placed inside the frame-frame.

The plank bed is assembled in the same way.

Finishes and decor options

Step-by-step instructions for assembling a bed from a bar do not take into account finishing. Because wood is already a beautiful material. And it is not necessary to bring the surface of the beams to the state of a polished or polished plane.

Sometimes it is enough to apply a stain to just change the shade. But more often the timber is covered with a colorless varnish. At the same time, wood defects also do not have to be repaired.

But there are many wood finishing technologies. Here are a few that are often used:

- Coloring. Acrylic-based paints are best suited for wood. The reason is that the paint lays down evenly, without leaving streaks, the structure of the tree is clearly visible through the applied layer. By choosing a shade, you can decorate a bed made of timber for a certain style of bedroom interior. For example, cold blue is well suited for the Scandinavian style, yellow, sand or brown will fit into the classics. Peach or orange is for country music.

- Decoupage. This technology for decorating old pieces of furniture was invented by the French. Drawings are cut out of colored napkins, with which the surfaces of the beams are pasted over. Ready-made pictures are sold in stores. Depending on the style of the room, they are also selected.

- Stencils. They are also sold in a wide variety of stores. Application technique - the stencil is applied to the surface, and the free areas are wetted with a sponge moistened with paint. You can use paint in spray cans.

- Upholstery. For this, a fabric is used, which is upholstered in areas that require decoration. Usually this is how the headboard is designed. But it makes sense to consider the supporting beams of the frame, especially the wide ones. Therefore, their cover may not cover completely.

A bed made of timber is furniture, though massive, but reliable. It will serve more than a dozen years for more than one generation of owners of the house. Even made by hand, it is original and will decorate the bedroom.

Is there anyone who made his own bed out of timber? Write in the comments how you did it, what design you chose, what difficulties you had to face.