Most upholstered bedroom furniture is simple in design. If making a wardrobe, walls or wardrobe will require certain knowledge and skills of a carpenter, then making an armchair or sofa bed with your own hands is easier. You just need to make a frame and fit the back and base of the sofa with soft upholstery.

The content of the article:

-

Design features

- Photo examples

- Schemes and drawings

-

What tools and materials will be needed

- What glue can be used

- Sofa bed assembly technology

-

Step by step instructions for creating

- Assembling the box of the fixed part of the sofa bed

- We make a sidewall with a shelf

- Assembling the sofa bed box

- We build a movable part of the sofa

- Wood finish with protective coatings

Design features

In practice, things are more complicated. The design of a homemade folding sofa bed must at least meet 3 main criteria:

- Unfold and fold without the use of additional tools.

- Have sufficient stability, both in the folded and unfolded position.

- For construction at home, you can use any parts and mechanisms, except for the finished parts of the sofa bed, manufactured in a factory way.

The last point means that the process is an assembly of the design of the original circuit, and not an overhaul of factory furniture. Since how to build a full-fledged sofa bed with your own hands without pillows, a mattress, back lining and armrests is almost impossible, then all the soft details can be borrowed from old sofas, armchairs, beds.

Photo examples

The simplest sofa bed is assembled from pallets. Each euro pallet will need to be sanded and varnished. In fact, this sofa bed design resembles a toy constructor. You can fold the pallets one on one, add a fixed back to the bottom row, you get a sofa.

If you lay out the pallets on the floor, you get a typesetting podium, and after laying the pillows, it is quite possible to use it as a bed or a double bed.

The pallet option can be used as additional bedroom furniture in the country house or even as a place to relax on the veranda of a private house.

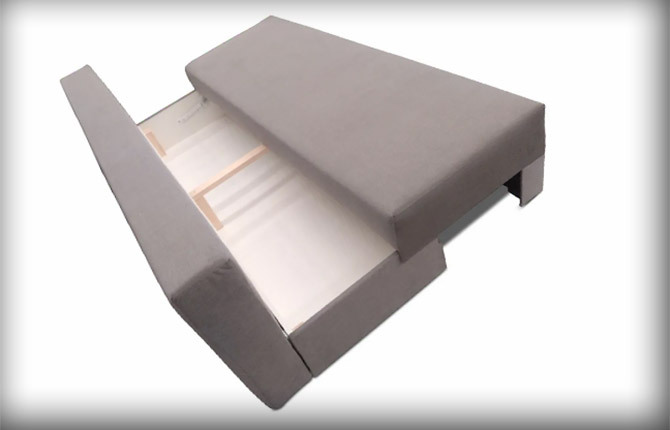

For an apartment, furniture with a pull-out bed is more suitable. In fact, this is a classic version of a sofa bed of a sliding design, which is mass-produced by furniture workshops and enterprises.

When assembled, the sofa bed is practically no different from ordinary upholstered furniture. In order to bring it to a sleeping position, you need to remove the pillows (they also serve as backrest upholstery) and push the front pillar.

A sofa bed can be made according to the scheme with a reinforced berth. In this case, the seat can be moved, but with a slight rise in this part of the body. The backrest simply tilts into the freed space.

The sofa bed looks simple, but the movable part of the body is mounted on a special support, which makes lifting easier. The scheme of the mechanism is quite complicated, it is most likely impossible to make a support with your own hands. But in general, the idea is interesting, so it makes sense to build a sofa bed of such a scheme only if there are details from old furniture.

Another homemade sofa bed project, the scheme of which is also used in the industrial manufacture of bedroom furniture. This is a pull out sofa bed.

When folded, it resembles a small children's sofa with a high seating position. Approximately such models, similar to couches, are often installed in rest rooms, and even in living rooms in front of the TV.

To expand the sofa bed, you must:

- Remove pillows.

- Tilt the backrest, install it on folding legs-supports.

- Raise and turn in the direction "towards you" the upper part of the seat of the sofa. The side rails are used as supports for the reclined part of the sofa bed.

This is one of the most successful designs, but you can’t call it easy to manufacture. The soft part of the seat of the sofa bed also unfolds, so it needs to be spread over the entire surface of the bed.

The most unusual model of a folding bed can be called the design below. This is a completely original project in which the double bed folds upside down.

To turn it into a full-fledged sofa bed, you just need to add a backrest, soft pillows and seat upholstery to the design. In addition, you will need a mattress and a set of bedding.

Schemes and drawings

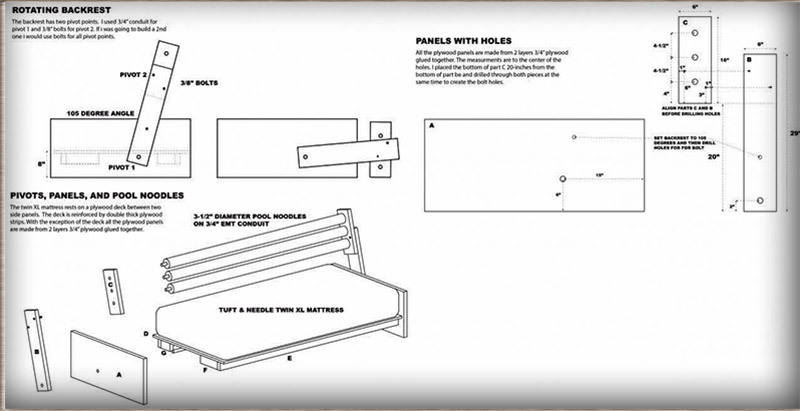

A pull-out sofa bed doesn't have to be big. It may well be a single bed with the possibility of increasing the width of the bed due to the reclined back.

If you look at the photos and drawings of a folding sofa or accordion, it becomes clear that the back is the most difficult to manufacture.

It consists of 2 parts, which makes it possible not only to put it down, but at the same time to increase the width of the sleeping area of the sofa bed.

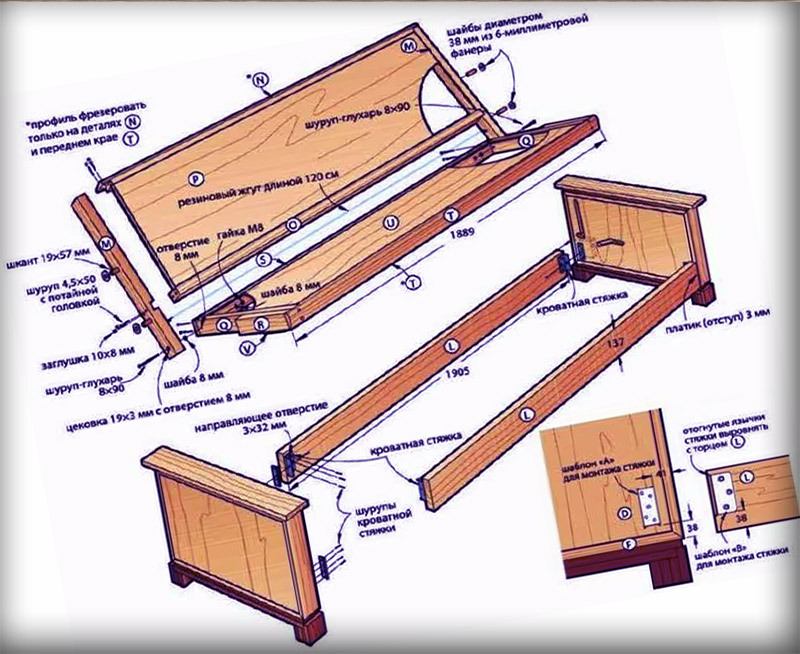

A sliding version of bedroom furniture can be built according to the frame scheme. The basis of the sofa bed is made in the form of a box.

For the manufacture of the frame, a wooden beam 45x45 mm is used. The frame of the back of the sofa bed is also assembled from it. If necessary, the frame and frame can be welded from a profile pipe 25x25 mm. The design will turn out a little heavier, but more stable and stiffer.

The back is best made from lumber, sheathed with plywood and sheets of expanded polypropylene. The sidewalls can be made in any way, you can even use parts from an old chair. Replace the upholstery and put on the sofa bed.

It is better to make the retractable part from thick plywood or knock it down from 45x45 mm bars. This is the most vulnerable part of the sofa bed, it will have to be moved regularly, so the durability of the furniture depends on the strength of this part. According to the plan, it should move on plastic wheel supports, but in practice this scheme does not work very well due to deformation and jamming of the wheels.

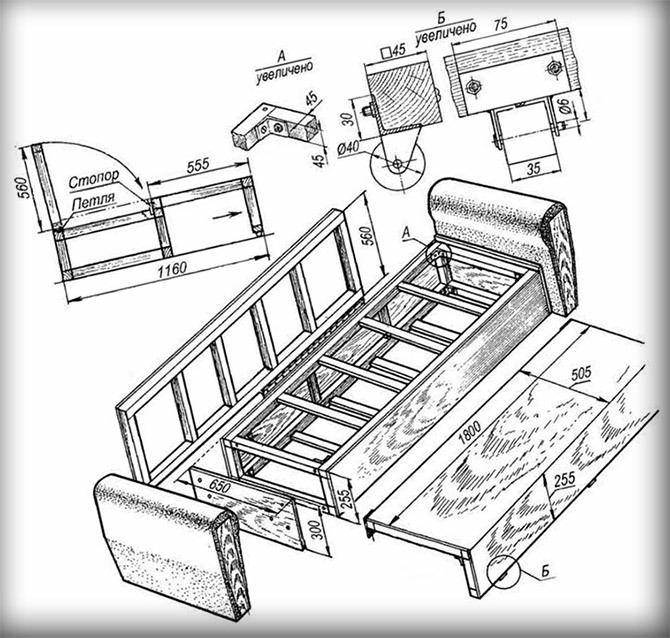

A sofa bed can be built according to a folding scheme.

The basis of the sofa is a box assembled from 2 backs of two sidewalls (lags). The parts are interconnected using steel corners and self-tapping screws.

The most complex folding part of the sofa bed is a U-shaped frame, the upper part of which is used as a backrest (in the folded position), and a frame is attached to the bottom seats. The connection is made using studs or self-tapping screws. This whole butterfly-shaped design is fixed on the backs with the help of screw-in studs, they work like rotary axles.

It is clear that this is only the wooden frame of the sofa bed, it will also be necessary to make fabric lining and soft pillows.

For the first experience of making a sofa bed, it is best to choose a relatively simple scheme of sliding furniture. This design does not have complex swivel joints, hangers or supports, so it can be made even with minimal carpentry experience.

What tools and materials will be needed

For a sofa bed, it is best to use 18-20 mm thick plywood. It produces the most durable furniture. But the high cost of plywood sheets sometimes does not allow making the entire structure plywood. To reduce the cost of building a sofa bed:

- The main details of the box are made of wide (35-40 cm) boards 30-40 mm thick.

- For the frame under the seat and the crate, a pine beam 50x50 mm or 75x50 mm is used.

The boards used to make the sofa bed need to be perfectly flat. This fact should be paid special attention when buying material. Otherwise, the furniture board glued from the boards will be uneven. Therefore, the purchased material, before the construction of the sofa bed, will need to be cut on the machine, both along the planes and along the end surfaces.

In addition, you will need wood glue, self-tapping screws, furniture screws with a conical head, pegs for cutting dowels, and an impregnating wax composition. It is used for bedroom furniture installed on verandas or covered terraces.

To form the soft part of the seat and back of the sofa bed, you will need to sew pillows or make a mattress based on polypropylene foam with a thickness of 60-70 mm. For a homemade sofa bed, you can sew a soft lining stuffed with scraps of interlining or foam rubber.

It would be possible to use 20mm thick plywood, this would even reduce the overall weight of the sofa bed. But the appearance of the furniture would obviously be less expressive, since the wood after waxing and polishing looks much more attractive than plywood.

For manufacturing, you will need a fairly large list of tools:

- Joiner's workbench.

- Table circular saw or electric jigsaw. The thickness of the blanks for the manufacture of sidewalls and backs is 25-40 mm, so a powerful tool is required.

- Electric drill with a set of conventional and cylindrical drills.

- A set of joiner's clamps from 120 mm to 700 mm.

- Carpenter's hammer with a rubber or silicone nozzle.

- The grinder with a tape abrasive element. You can additionally use a vibrating grinder for finishing operations. Automotive disk models can also be used, but they leave risks on the surface of the tree.

- A vice in which workpieces up to 100 mm thick can be clamped.

- Conductor tablet or square for drilling oblique holes.

In addition, you will need a marking tool - a caliper, tape measure, carpentry squares, markers.

What glue can be used

Now the important point - glue. To glue the details of the sofa bed, you can use any modern glue for carpentry. It is better if on a polyurethane basis. Solid adhesive compositions cannot be used. Fixing with glue must remain plastic. Polyester or epoxy adhesives hold up well after hardening, but after a couple of months the adhesive seam tears off the top layer of wood, and the joint falls apart.

The exception is casein glue, which is absolutely safe and non-toxic. The granules are diluted in cold water and heated in a metal container in a water bath. It is diluted an hour before work, as a rule, a 200 ml can is enough to glue all the details.

Casein glue can be made in 5 minutes. According to the recipe, you need to mix 100 grams of cottage cheese with 40 ml of ammonia. It will turn out a transparent viscous mass, which can perfectly glue and putty any tree.

Sofa bed assembly technology

Any cabinet furniture according to existing standards can be assembled either using the classic tenon-groove connection, or using wooden pins or dowels.

To assemble the body of a homemade sofa bed, the first option would be preferable, since the tenon groove provides higher torsional or bending rigidity. But this method is quite complicated for the first experiments on the construction of bedroom furniture. Therefore, assembly operations are performed on dowels, with sizing of the joined surfaces with casein (any polyurethane) glue.

It is impossible to assemble and join parts only with self-tapping screws, even if the main elements are made of plywood. On self-tapping screws, a sofa bed, chairs, armchairs will stand for a maximum of several months, after which it is quite difficult to repair the furniture due to cracks.

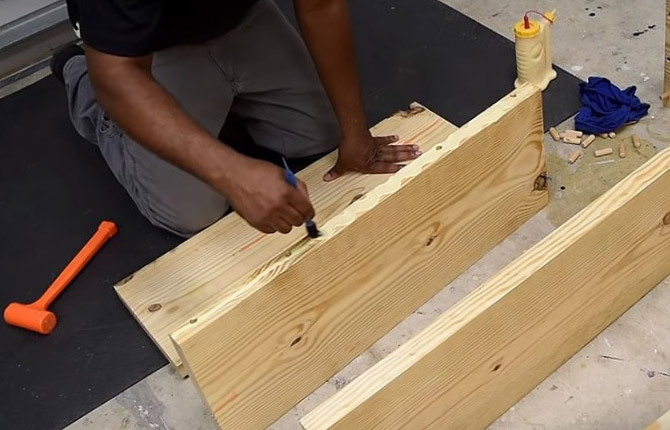

The process of skewed docking is laborious. For example, to end-join 2 boards with dowels, it is necessary to drill holes in both parts.

The main difficulty is to drill the hole correctly. It should correspond to the diameter of the dowel or be 0.1 mm smaller than it (for adhesive fit). In addition, the axis of the hole must be strictly perpendicular to the end surface. Therefore, for drilling, special guides are used - conductors, which are installed at the drilling point and fixed with a clamp. Holes are also drilled on the second board.

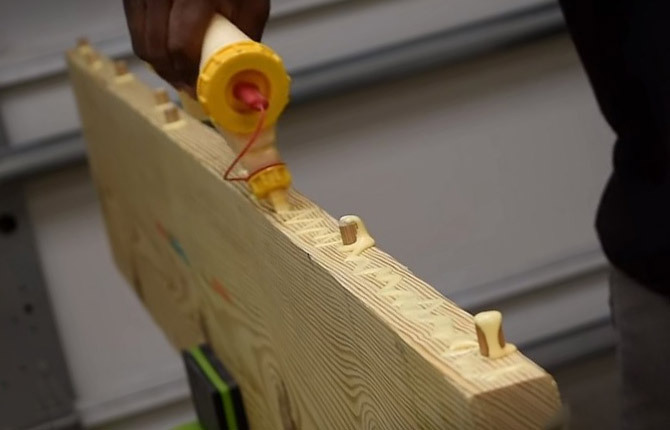

After drilling, dowels (wooden pins) are hammered into the holes, and glue is applied to the end surface.

Next, the boards are joined, knocked out with a hammer and tightened with clamps.

The result is a furniture board, from which you can make not only a sofa bed, but any home furniture.

Step by step instructions for creating

For the manufacture of a sliding sofa bed, first of all, it is necessary to correctly cut the blanks. Since the frame will be glued on dowels of forty boards, a desktop cutting machine with a manual circular saw drive is used for cutting.

In another way, at home, cutting boards with high quality will not work. It is required not only to cut the blanks to size, but also to ensure a right angle between the cutting plane and the surface of the forty board.

In addition, it will be necessary to cut blanks for the lathing of the plane of the movable part of the sofa bed.

Assembling the box of the fixed part of the sofa bed

The design of the sofa consists of a base part or a box and a movable part - a sleeping bag. The fixed part will be glued from one simple sidewall, backrest and sidewall-shelf.

A simple sidewall and back must be glued on dowels from two pairs of boards (blanks are cut out 2x80 cm and 2x210 cm each). If properly connected, then both parts of the sofa bed will look as if they were cut from the same solid wood slab.

The blanks will need to be sanded with a grinder. This will help seal the seam and remove any remaining adhesive. There is no need to do any additional puttying at the joints of the glued boards.

The next step is to try on and make dowels, make holes on a simple sidewall and back. You need to connect the parts at a right angle, as in a box or bookshelf.

A preliminary fitting of the details of the sofa bed will help to check whether the joint is correctly made and whether mistakes have been made. This is where it will be seen how correctly and efficiently the boards were planed.

We make a sidewall with a shelf

This part of the sofa bed is more like a bookcase. It will be necessary to cut 3 pieces of 70 cm and two of 40 cm and 20 cm high from the board. The edges of the blanks are cleaned with a grinding machine. If possible, it is better to polish the ends of wooden blanks with a felt circle planted on a drill.

We assemble the sidewall-shelf, like all the details of the sofa bed, with the help of dowels and glue. After assembly, the body will need to be fixed with carpentry clamps.

During the assembly process, you need to make sure that the tightening force on the clamps is approximately the same, otherwise, if you pinch at least in one place, gaps may appear.

After the glue has dried, you can try on how the sidewall-shelf fits into the back of the sofa bed.

Assembling the sofa bed box

First of all, you need to connect on the dowels and glue the back of the sofa bed and a simple sidewall. To prevent the joint from opening during the drying time of the glue, both parts must be fixed with clamps.

The next step is to connect the second edge of the back of the sofa bed with the side shelf. To do this, we move the part to the back, as tightly as possible, then fix it with a clamp and cut out the wooden blank of the former (upper part) of the sidewall.

Further:

- We adjust the former in size in length.

- We drill holes on the workpiece, on the back of the sofa bed and on the sidewall itself.

- We insert the dowels, coat with glue and tighten the entire block with clamps.

The connection on the dowels must be made not only along the former, but also in the middle and lower boards. Only then will the load be distributed evenly over the entire surface area to be bonded.

Dowel fastening works perfectly when assembling cabinets and shelves. For a sofa bed, its strength is clearly not enough, as furniture for sitting and relaxing is under heavy load.

Therefore, as soon as the glue dries, six through holes for self-tapping screws need to be drilled from the back of the back. Drill diameter 3.5 mm. Each sidewall is additionally pulled to the back with six self-tapping screws. Holes can be puttied with carpentry putty.

The next step inside the box is sewing a frame from a bar 50x75 mm. The slats of the crate and the mattress will rest on it.

With the help of a square and clamps, you will need to adjust the position of all four bars so that the corners are straight, otherwise the entire frame of the sofa bed may slightly “bevel” to the side.

Inside the frame, we sew in a spacer bar, otherwise the lathing slats will strongly sag under the weight of people sitting on the sofa bed.

You can sew in 2 longitudinal spacers, but with a smaller section, for example, 50x50 mm. The ends of the beams are connected to the frame with oblique cuts of self-tapping screws only after the position of the spacer is aligned with the level of the horizon and the plane of the frame. Tighten one self-tapping screw on the left and right. That is, a total of 4 self-tapping screws will hold the spacer.

For one person weighing up to 70 kg, this is enough. If the sofa bed is made for a family, then 4 self-tapping screws will not be enough to compensate for the deflection of the battens. Therefore, many craftsmen additionally sew spacers on each end with a pair of wooden triangles cut from board scraps.

After stuffing the timber, all parts of the sofa bed, especially those with which human hands will come into contact, must be processed with a grinder. Initially, with a large emery cloth, we remove the irregularities at the joints, then we grind the wood with a fine grain to a smooth surface.

It remains to fill the laths of the crate. For cutting blanks, it is recommended to use a simple board with a section of 100x20 mm. But in practice, slats of this section withstand loads only if they are cut from oak or acacia. Ordinary pine or spruce are not strong enough. Therefore, you need to either choose a suitable tree, or increase the cross section to 20x120 mm or 25x120 mm. It is clear that the slats should be free of knots and cracks.

We lay out the cut boards on the frame sequentially, with a step equal to the width of the workpiece plus 10-15 mm. To speed up and simplify the process, you can use a rail template with two rubber erasers attached to the end for drawing.

Reiki can be fastened with self-tapping screws or a furniture bracket. In the latter case, you will need a pneumatic stapler or hammer. The fastening strength is low, but the furniture bracket will not split the timber.

If you use self-tapping screws, then, firstly, no longer than 25 mm, and secondly, you will need to drill through holes 4 mm in diameter in the rails. So that the self-tapping screw does not split the rail when screwing it into the body of the beam.

We build a movable part of the sofa

For the manufacture of the retractable part of the sofa bed, you will need a lathing rail, two 50x75 mm beams and one board, which will simultaneously serve as a side or lower part of the facade.

First of all, you need to fix one of the beams on the outside of the support frame of the sofa bed. This can be done with a self-tapping screw, but it is best to use a pair of carpentry clamps. The beam will need to be leveled so that it goes under the ends of the previously laid rails with a small gap of 2-3 mm.

Now the most difficult thing, you need to cut the board board to size. Typically, the height of a sofa bed bed above floor level does not exceed 35-37 cm. But since the sofa is homemade, the dimensions were chosen arbitrarily, it may turn out that the width of the board (blank) will turn out to be less than the level of the planks. Therefore, when cutting out parts, even before assembling the sofa bed, you need to select the widest board and leave it for the board.

We install the finished part on the edge so that it touches the plane of the beam, fixed with a clamp.

Next, we transfer the markings of the upper edge of the beam to the board and remove both parts from the sofa bed box. Now you need to fix the beam on the inner surface of the side along the marking line. This will require 5-6 carpentry screws 60-70 mm long.

The next step is to fill the remaining battens of the crate onto the beam of the movable part of the sofa bed. In this case, self-tapping screws 25-30 mm are used for fastening. Before wrapping each fastener, it is imperative to drill a hole with a diameter of 2.5-2.7 mm and chamfer under the conical head of the self-tapping screw. This is the only way to completely drown the fasteners into the tree and not split the rail.

If an old, very dense oak was chosen for the lathing slats (and the nominal one is needed), then problems may arise with the tightening of the self-tapping screws. You can, of course, try to pick up a slightly larger diameter drill for the holes, but you can easily loosen the fasteners. Therefore, for such cases, self-tapping screws are dipped in laundry soap or wiped with a paraffin candle before screwing in. This is a more reliable option.

Before laying the slats, you can apply several dots of glue to the supporting surface of the timber. You need to wrap the screws manually or at the lowest speed.

It remains only to check how freely the sofa bed extends, and to remove the chamfers from the edges of the spacer bar and from the ends of the lathing rails with a file.

Wood finish with protective coatings

Now you can disassemble the sofa bed, remove the moving part and treat the wooden parts with stain or wax impregnation. This could be done in parts during the furniture manufacturing process, but in this case stains could appear, and the sofa itself would be divorced.

Therefore, the decorative coating is applied once over the entire surface.

It remains only to lay the mattress, make the upholstery of the back and lay the pillows.

Building a sofa bed with your own hands is not so difficult even for a novice cabinetmaker. You just need to take care of high-quality material in advance and not save on renting a high-quality tool. It is impossible to make beautiful furniture with one plane and a saw.

Share your experience in making sofas, which designs, in your opinion, can be considered the most successful for DIY construction. What can be changed or added.