It would seem that there is nothing easier than choosing a dowel for a brick. Moreover, it is more familiar and easier to plant fasteners in a solid brick wall than in weaker foam concrete or a gas block. However, in this case there are a lot of nuances that you need to know about before making a choice in favor of a particular model of dowels.

The content of the article:

- Is a classic dowel suitable for attaching to a brick

- What to look for when choosing?

-

What types of dowels are suitable?

- Dowel-universal

- Imported dowel universal special shape

- Triangular universal dowel

- German station wagon 8x60 mm

- chemical anchor

-

Instructions for installing the dowel in a brick wall

- Installation of classic plastic dowels in solid and hollow bricks

- How to install a nylon self-twisting dowel

- Installing the facade dowel

- chemical anchor

- What is the difference between dowels for concrete and brick?

- Results

Is a classic dowel suitable for attaching to a brick

There are several ways to mount on a brick wall, including using a classic plastic dowel plug. Until recently, it was a simple nylon or polyethylene cork with a hole for a self-tapping screw. It didn’t matter to hold such a dowel, but if you increase the number of fastening points, then it was possible to fix a kitchen cabinet or shelf on a brick wall.

The modern classic dowel is represented by a fairly large assortment of plastic plugs that differ in size, surface shape and material. And all of them can be used for mounting on a brick wall.

The traditional design of dowels for bricks:

- cylindrical plastic cork with several slits;

- conical nose to simplify laying inside the hole in the brick;

- a belt at the end that prevents the dowel from falling into the depth of the hole;

- side tendrils that improve adhesion to the masonry material.

The best models of dowels with a diameter of 8 mm are able to withstand a pull-out load of 100 to 300 kg. More simple universal dowel plugs of the same size are held on a brick wall of 60-80 kg.

If you need to get a mount on a brick wall for a load of 500-600 kg, then it is better to use chemical anchors.

It is clear that the stud, glued into the brick, can withstand a large load. But that's not even the point, the bearing capacity of a chemical anchor, unlike the usual classic dowel, does not depend on the characteristics of the brick.

The problem is especially brickwork. It does not have two identical sections. Therefore, on a glued anchor, the strength does not depend on the installation point or the defects of the fired clay, but on a conventional dowel it can vary greatly.

What to look for when choosing?

The strength of the fastening largely depends on which brick to fasten the dowel and where exactly the fastening point will be located. Silicate white walls usually hold fasteners better, do not crack even when using anchors. The strength of fastening on a slotted hollow brick made of clay, with the right choice of dowel, can be even higher than that of a solid stone.

Ordinary brick is red or purple-yellow. The first option is normal firing, the second is burnt. Due to improper firing and a high content of aluminum oxide, the material is hard, brittle, plus a large number of cracks.

In both cases, the dowel inside a solid brick can “sit” firmly and reliably, but it happens that it falls out if it gets into a hidden crack. Much depends on which dowel to choose.

There are three options for installing cork on a brick wall:

- directly into the body of the brick, stepping back from the edges by 2-3 cm;

- in a vertical seam;

- in a horizontal inter-row seam.

If the masonry is old enough, at least 10 years old, laid on a high-quality mortar, then you can beat the dowels into the horizontal seam between the bricks. It is clear that initially you need to check the strength of the cement joint with a chisel or screwdriver.

Often, installing a dowel in a seam provides a higher fastening strength, but only if the bricklayer did not save on mortar, and this is very rare. But if you already had a chance to beat the dowels between the bricks, then you need to hammer only inside the horizontal seam, and the diameter of the cork should be at least 10 mm. It is better to refuse installation in a vertical joint.

Healthy: Types of dowels for foam block

What types of dowels are suitable?

In fact, not only classic dowel plugs are used for wall fastening. In addition to them, five more types of fasteners are used for brick walls:

- butterfly dowel, both plastic and metal options;

- brass split anchors;

- steel wedging anchors with reverse cone;

- front fixture for fastening on walls of heavy designs;

- chemical anchor.

From the list of the most commonly used types of fasteners, dowels and anchor models for fastening on drywall, foam blocks and aerated concrete should definitely be excluded. Such fasteners have almost zero bearing capacity.

For fastening on a brick wall of very light objects, you can use a dowel-nail. It can be made of polypropylene or nylon, but this has little effect on the strength of the fastening, even on sand-lime brick. The maximum load for such a model is considered to be 60 kg.

Dowel-universal

The most popular type of dowel is made of nylon, size 8x50 m, with a split slot and annular knurling on the outer surface. The popularity of fasteners is due to low cost and easy installation.

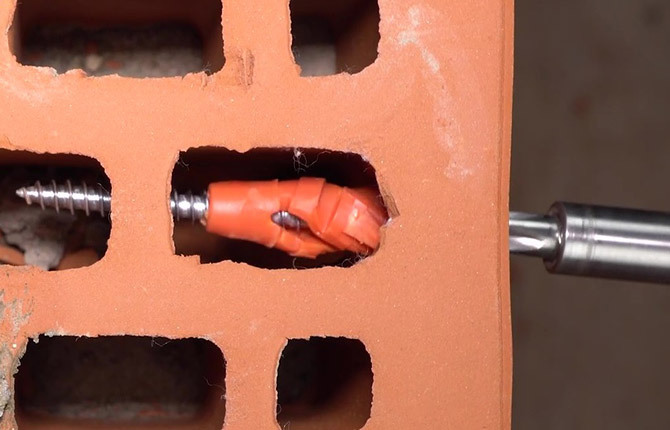

With proper installation, the station wagon is able to withstand an axial pull-out load of up to 100 kg. In the case when a universal dowel is driven into a hollow brick, the load resistance increases by 10%.

Imported dowel universal special shape

It differs from the previous one in side lobes and a rectangular body shape. The design of the plug is thought out in such a way that when the self-tapping screw is screwed in, the wedging of the body occurs in one plane.

It costs 2.5 times more than the previous model, but the load capacity is limited to 80 kg. But in a hollow brick, due to the collapse of the dowel and the formation of a cork, the attachment point is able to withstand up to 170 kg of pull-out load.

Triangular universal dowel

Type "U", a cork made of polypropylene with three faces, a cut and annular grooves on the surface. The cost is 3 times lower than the previous dowel.

This is one of the best dowel options for when you need to install a large number of anchor points. The cork can withstand a pulling load of up to 160 kg.

But for a hollow brick, it is better not to use the trihedral option, even with proper installation, the fastener strength drops by 20%, from 160 kg to 130 kg.

German station wagon 8x60 mm

This type of dowel differs from previous models in that the body is made of two types of nylon: soft (red) and hard (grey). The cost of such a cork is about an order of magnitude more than that of the previous sample.

In a solid brick "German" has a bearing capacity of 280 kg. That is, this is the best dowel if you want to make one attachment point, but with increased strength. In hollow brick, the dowel can hold up to 10% more pull-out load. The whole secret is that when the screw is screwed, the plastic is crushed in a special, precisely calculated way, reliably clogging the metal in the hole.

Important! If you turn the screw too fast, the threads can cut through the inside surface of the plastic, and the fastener will fall apart.

chemical anchor

Universal, but very expensive solution. It can be used for any purpose, fasteners with an M8 stud can withstand a load of up to 900 kg. But due to the high cost, the anchor is used only for especially critical fastenings.

In hollow brick, the chemically filled anchor can withstand a load of up to 1000 kg. In this case, the strength will increase for several more days. When the polymer finally hardens, the resistance will increase by another 3-5%.

Instructions for installing the dowel in a brick wall

The installation scheme in a brick is no different from installation in other materials. But if you have to put the dowel in a burnt brick block, then it is better to immediately install a drill with a carbide plate into the cartridge. A high-quality brick, whether solid or hollow, is drilled quite simply with an ordinary metal drill. White silicate can be drilled even with a black drill on wood.

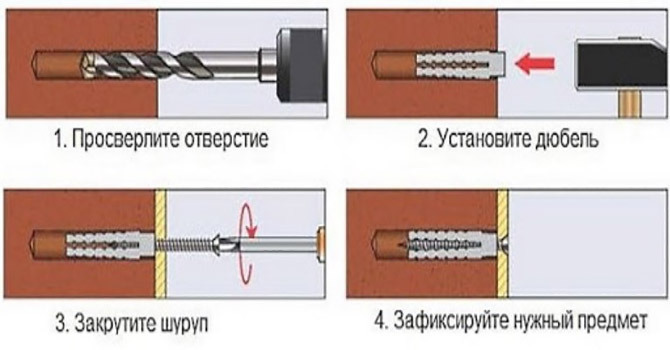

Installation of classic plastic dowels in solid and hollow bricks

The easiest way is to install a universal polypropylene or nylon dowel plug. Almost all low-cost models have a cylindrical body with a support side and a pointed nose. The plug is held inside the hole only by pressing the annular notches against the inner walls of the hole. Therefore, you need to choose the right diameter of the drill, it should be 1-1.5 mm smaller than the cross section of the cork.

Next, a hole is drilled in the brick, it is made with a small margin in depth. The dowel is inserted into the hole by hand. If the drill size is correct, the cork will go in about half way. The rest will need to be hammered in with a hammer until it settles at the level of the annular rim.

If the dowel needs to be placed in a hollow slotted brick, then the diameter of the mounting hole is chosen a little less. The nylon body inserted by hand should go in about 1/3. Next, a self-tapping screw is inserted into the cork, twisted half the length. The rest must be wrapped with a screwdriver, while inserting the dowel into the hole in the brick block.

You can, of course, do it according to the instructions, hammer the dowel-plug, then wrap the self-tapping screw or hammer in the nail. But in this case, the fastening strength is 20% lower.

How to install a nylon self-twisting dowel

All universal dowels with a profiled surface, cuts, antennae are installed according to the following scheme:

- A hole is drilled according to the size indicated on the marking. For example, 8x65 mm means that you need to work with an 8 mm drill to a depth of 65 mm.

- The dowel-plug is inserted by hand into the hole and clogged with light blows of the hammer on the level of the side (if any).

- A self-tapping screw is wrapped inside the clogged cork.

If you make the hole 1 mm smaller, then the dowel will either not go inside the brick due to the “antennae”, or it will deform and break in the middle. Only a slight increase in the hole in a solid brick is allowed, and only at the entrance, and for dowels with a length of 80 mm or more.

For a hollow slotted brick, the hole is made exactly according to the dimensions on the marking. Accordingly, the fixation of the self-tapping screw occurs due to the self-twisting of the dowel into a tight cork.

Advice! When tightening a self-tapping screw or screw with a screwdriver, it is important not to overtighten the fasteners. You need to catch the moment when you need to stop the tool, otherwise the screw will cut out a part of the plastic with a thread and fall out of the masonry without any effort.

Installing the facade dowel

This type of fastener is used for installation on brick walls of heavy metal structures. The length of the dowel screw is 120-180 mm. Facade dowels are installed on hollow and solid bricks according to the same scheme.

Initially, a hole is drilled, then a dowel plug is hammered in and a screw is screwed in. No self-closing plug is formed. When screwing, the plastic is unclenched with great effort to the inner walls and securely fixes the screw.

This is the only fastening scheme that can withstand any type of load, even variable, twisting and bending.

chemical anchor

The installation scheme for hollow and solid bricks is practically the same. The only caveat is that the anchor can be installed in a full brick without a mesh sleeve, while inside a hollow one - only with a mesh.

First you need to drill a hole, the dimensions are taken from the marking of the anchor. To improve adhesion, the cavity is cleaned with a brush and blown with air. Then a plastic mesh is installed, and a polymer resin, usually polyester or epoxy, is squeezed into it. It remains only to press the pin inward with your hand and fix it until the resin has completely hardened.

What is the difference between dowels for concrete and brick?

Most often, fasteners designed for installation inside a concrete wall do not adhere well to brick. The same dowels or dowel-nails are "tightly" fixed inside the concrete only due to the enormous contact strength of the material.

If you wrap the dowel correctly or drive a nail into the dowel, then the fastening will be held due to a very strong deformation of the material. The deformation is small, but the bursting force is huge, and the concrete does not crumble or crack.

Brick, as a rule, does not withstand contact pressure, the walls of the hole begin to crumble. For example, an anchor with a split brass sleeve inside concrete can withstand a load of up to 300 kg.

If you hammer fasteners into brickwork, then the maximum bearing load will be only 60-70 kg.

The situation is even worse with the installation of anchors with a reverse cone. After drilling, fasteners are installed with a small gap to reduce pressure on the walls of the hole. But still, even with careful and moderate tightening of the screw, the anchor cone almost completely destroys the front of the brick.

If left not fully tightened, the fastening will turn out to be weakened, the walls will gradually crumble, so the anchor will quickly fall out of the hole.

Results

Picking up a good inexpensive dowel for brick walls is quite simple. Most classic models can withstand loads up to 90 kg. This is quite enough for most household cases. If heavy-duty fasteners on the facade are required, then specialized models with an increased length of the cork can be used.

Tell us about your experience installing fasteners on brick walls. Which of them turned out to be the most reliable and durable? Write comments, share the article on social networks and bookmark it.