Dry screed is a simplified floor leveling technology that does not involve the preparation of a concrete mixture. Instead, lighter materials are used, such as expanded clay or vermiculite. This makes the job much faster and easier. The pros and cons of this method, as well as the laying technology, are described in detail in the presented material.

The content of the article

- The essence and structure of dry screed

- Pros and cons of technology

- Dry screed materials

- Step by step installation instructions

The essence and structure of dry screed

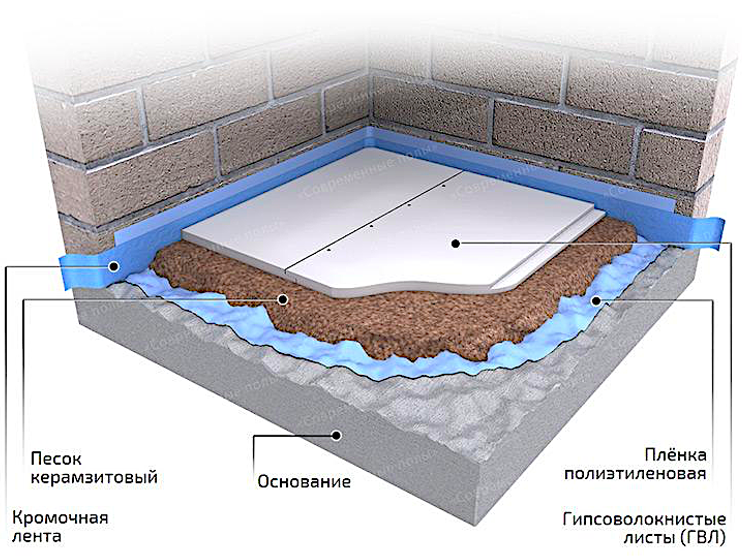

First of all, you need to understand what a dry screed is. This is one of the most common floor leveling methods, in which cement-sand mortar is not poured. That is, it is a simplified technology that differs significantly from the installation of a traditional concrete floor. We can say about a dry floor screed that it is an alignment that consists of 5 layers:

- Separating - it is laid directly on a concrete or other base. It serves to protect against moisture - as a rule, a vapor barrier or polyethylene film is used for this. Bituminous, corrugated or perforated paper is placed on wooden bases.

- Edge tape - a layer that is laid out in the gaps between the edges of the floor and the wall surface. Performs soundproofing function.

- We can also say about the dry floor screed that this is a leveling layer - the basis of the whole structure. As it is used fine-grained material with a moisture index within 1%. Usually it is expanded clay sand with particles no more than 5 mm. But since it sags over time, it is better to use a mixture of bulk flooring from well-known brands.

- When the surface does not have significant flaws, height differences of more than 10 mm, instead of dry backfill, you can put expanded polystyrene plates. It not only provides a smooth surface, but also has thermal insulation properties.

- Finally, the last layer is the finish. These are sheets of gypsum fiber that are used as a base for flooring. One of the most reliable options is glass panels with connectors that are easy to install with your own hands.

Pros and cons of technology

It can be seen from the description that a dry screed is a multilayer structure, which, unlike concrete, does not require pre-mixing of the mortar. Due to the peculiarities of the materials used, this technology provides several tangible advantages at once:

- light weight, can be used on any floors;

- Smooth surface;

- simple installation, without "dirty" processes;

- saving time - no need to wait until it dries;

- good heat and sound insulation;

- the top coat can be laid immediately after the installation of the screed is completed.

If we talk about the shortcomings, there are not so many. It is important to understand that a dry screed is a method that is only suitable for ordinary residential or commercial premises. It is not worth using it on the floor in a bath, shower, bath, pool - it is appropriate to use a concrete screed here.

Dry screed materials

It is clear that a dry screed is a simplified floor leveling technology. For this, bulk compositions based on different components are used. The main options are:

- Expanded clay of average fraction. Good insulation, light weight and porous surface. The material is affordable, so it is often used for screed. The weight of a cubic meter ranges from 250 to 600 kg.

- Vermiculite is another lightweight, low density material. The weight of a cubic meter is only 160 kg. It should be borne in mind that for laying the floor it is necessary to take only the vermiculite that has undergone swelling.

- Perlite is a natural material, a rock of volcanic origin. Differs in ease and durability.

- Kompevit is a material based on rounded expanded clay, no more than 4 mm in diameter. At the same time, it is denser, so it does not sag over time, it provides a smooth surface.

Understanding a dry screed, what it is, it should be noted that in some cases you can do without without backfill, if the floor surface is sufficiently even, it is enough to lay slabs of polystyrene foam.

Step by step installation instructions

Before starting work, you need to measure the room and determine what the minimum thickness of the dry screed will be. This indicator depends on the quality of the surface - the more even it is, the less backfill can be used.

On average, the value ranges from 30 to 50 mm. The minimum requirement is 15 mm. If the floor has serious defects, it is better to take a thickness with a margin - 50-60 mm. It is worth considering that the material consumption per square meter is from 54 to 75 kg (assuming that the thickness of the dry floor screed is 30 mm).

After the calculations, you can start work. The main steps are:

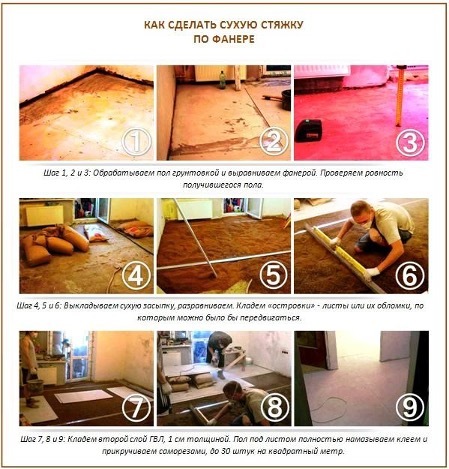

- Prepare the base - remove debris, clean the surface, if there are defects, they are filled with a dry mixture so that the floor is relatively even.

- A film of dense polyethylene is placed on the base, overlapping at least 25 cm. On the walls make an overlap of 10-15 cm.

- In the gaps between the walls and the floor, an edge tape is attached.

- Beacons are set around the perimeter using the building level.

- The mixture is poured, focusing on the estimated thickness of the dry screed. Start from the highest point of the floor (use a level to estimate the height).

- The embankment is leveled and rammed using a rubber mallet.

- The finishing layer is laid - for this you can use two-layer gypsum-fiber boards, fixing them with glue.

- At the very end, cut off the excess parts of the edge tape, clean out traces of glue. All joints are treated with putty.

After completing the described work, it is advisable to wait 2-3 days and then lay the floor covering. Thanks to this, the screed will gain sufficient strength and will last for many years.