A chopped sauna is still considered one of the best solutions. The log retains heat and at the same time does not turn sour from condensation. The only drawback is that you have to caulk the frame of the bathhouse, often with your own hands. The work is monotonous, requiring careful adherence to the technology of sealing joints.

The content of the article:

-

What materials are suitable?

- Jute

- Felt

- Lnovatin

- Moss

- Tow

- Why caulk the log house?

- Pros and cons of caulking

- How to caulk a log bathhouse?

-

Methods for caulking a log house

- Decorative caulking

- Included in the set

- Stretch

-

Log caulking technology

- Required Tools

- Preparation

- Main stage

- Corner processing

- Results

What materials are suitable?

For successful and durable caulking of a log house, you need to choose the right tools, practice your skills and select materials for sealing cracks. Moreover, if we compare all three conditions, the last one turns out to be the most important. Since an error in the selection of material usually appears only a few months after the completion of work on the log house of the bathhouse.

Most owners prefer to caulk their saunas:

- jute fiber;

- flax wool;

- tow or felt.

If you have material (sphagnum), you can caulk the frame of the bathhouse with moss. But this method requires careful preparation and drying of dried moss bundles. In addition, moss does not grow in the required quantity everywhere. It is much easier to use regular jute tape or tow.

Jute

Non-woven, fleecy material, similar in texture to felted wool, is made by needle-punched pressing of a wet mass. Easily stretches in all directions. The jute ribbon can be torn into strips by hand. Absorbs moisture well and allows air to pass through. One of the most popular and in demand stitches for embossing.

It is widely used by teams that undertake to caulk houses and bathhouses under contract. For a bathhouse, it is recommended to caulk the internal walls of the log house with jute tape, except for the steam room and rooms with high humidity. If you caulk the outer walls of a bathhouse, then with obligatory subsequent impregnation with a water-repellent agent. As a result, the seam acquires water-repellent properties, but does not prevent the escape of water vapor.

Felt

Denser than jute, it does not stretch well. Felt consumption is less, it is well suited for situations when you need to caulk a still young log house that has not completely dried and settled.

Lnovatin

It is made using needle-punched technology from flax fibers in the form of ribbons, with additional quilting with threads. More resistant than jute to heat, high humidity, and hot steam. It costs twice as much as first grade jute material.

Flax wool can be used to caulk a log house both inside and outside the bathhouse.

Moss

Caulking a bathhouse frame with sphagnum, even properly dried and sorted, is not an easy task. Its main difference from ready-made materials is its heterogeneous structure. If you use recycled fibers (tow-jute), then they have a uniform structure, so when sealing the inter-crown gaps on the log house of the bathhouse, the caulking turns out to be more or less uniform.

With moss everything is different: it is hard, you have to pull out tufts, twist them with a rope and push them with a spatula between the crowns of the log house. The only advantage of moss is its antiseptic properties. The material in the walls of the bathhouse does not rot or fall out like felt. Just don’t try to dig up a bathhouse box with already rotten crowns. This will not give anything, such a log house needs to be treated or dismantled.

Important!Sphagnum moss has a related plant, the moss dicranum wavy. They can be confused, but dicranum is too hard, you can’t caulk a bathhouse box with it. It is better to use it as inter-crown insulation when assembling a log house.

The moss placed between the crowns when assembling the log house remains sticking out until the bathhouse frame undergoes the first shrinkage. Then the stems are tucked, driven into the seam with caulk and cut with a knife.

Tow

Made from jute or flax fiber, sold in large bundles. The material is very similar to plumbing tow, stretches well and is rolled into a cord. To construct a bathhouse, the joints are often caulked with tow moistened with a water repellent. The properties of tow are almost identical to jute, but tow material is much more convenient for caulking old baths, especially the internal walls of a log house, where huge gaps often form between the crowns.

Why caulk the log house?

Most bathhouse owners believe that caulking is needed to preserve heat and protect the crowns of the log house. This is true, but only for a residential building built using log house technology. In this case, it is necessary to caulk the joints to avoid heat loss.

For a bathhouse the situation is somewhat more complicated. The operating mode of a chopped bathhouse made of logs or timber is somewhat different from the conditions of an ordinary residential building in the form of a log house. A huge amount of water vapor is generated in the bathhouse, even if it is a Finnish sauna.

Water vapor must be removed from the room, but at the same time condensing water must be blocked from the steam. If you choose the right material for the seam and caulk the joints, steam will escape, the walls will “breathe”, and practically no water will enter the inter-crown space.

After completing the bath procedures, the excess pressure of the hot atmosphere inside the log house squeezes air through the joints of the log house and dries it out. Therefore, acrylic sealant, which is often used for log houses, is not suitable; the seams only need to be caulked.

The bathhouse box also needs to be caulked to protect the crowns of the log house from rainwater, insects, and pathogenic microflora. Often the material at the joints becomes infected by birds that try to pull fibers out of the joint. They carry particles of soil on their paws, so the walls of the log house need to be looked after and periodically treated with a spray with water-repellent properties. Without water, pathogenic microflora quickly die under solar ultraviolet radiation.

Pros and cons of caulking

The main advantages of the technology are the relative cheapness of the material and the simple process of sealing the inter-crown joints of the log house. Using jute or linen is about three times cheaper than modern synthetic materials.

If caulked correctly, the flax wool will last on the walls of the bathhouse for up to 15-20 years without replacement. Jute caulking fades two to three times faster, especially when exposed to sunlight.

The disadvantage of the technology is the high cost of work. A good master will undertake to caulk a wall at a price tag of at least $1 per linear meter of seam. At the same time, the material itself can cost half as much.

You can caulk the frame of a bathhouse with your own hands, but the work is physically quite difficult, you have to work with a heavy hammer (1.5-2 kg). For every meter of joint you need to make up to one and a half dozen blows.

How to caulk a log bathhouse?

There are certain requirements for the quality of a caulked seam, but there are no uniform standards on how to properly caulk the walls of a bathhouse log. Therefore, most of the sealing technology is a set of rules on how to get the most dense and rigid seam possible without the use of adhesive or mastic materials.

The basic rules by which the joints of a log house are usually caulked:

- The sealing material must be driven into the joint to a depth of at least 5 cm.

- The sealing surface is formed from a tape or a bundle of fibers by pressing the ends inside the joint so that a roll of tightly compressed fibers remains on the outside.

- The seam bead should be elastic, compact and hard. The seal should compensate for possible changes in the inter-crown gap when heating or cooling the walls of the bathhouse.

- You can caulk a log house with any material, both inside and outside the bathhouse. After treatment with a water repellent, the seam seal acquires water-repellent properties, regardless of the nature of the fibers.

Usually they start caulking from the lower crowns in a circle and work their way up to the upper ones. Corner zones are caulked simultaneously with linear ones. It should be taken into account that only log houses that have undergone initial shrinkage need to be caulked. Otherwise, at the end of the shrinkage processes, the bathhouse box will have to be caulked again at the corners.

Methods for caulking a log house

There are three main options for laying material in inter-crown joints. The quality and reliability of the seam depend on what type of caulking was used and how exactly the master caulked the walls.

Decorative caulking

Typically used to improve the appearance of a bathhouse. For example, according to existing rules, it is necessary to caulk only before painting the walls of a log house, but after sanding the surface. Painting the bathhouse leads to the fact that the walls merge and the relief of the logs of the log house is simply not visible.

To emphasize the texture, a twisted cord with a diameter of 8-12 mm is laid on top of the main embedding roller. The log house takes on a more elegant appearance, but the decorative overlay does not in any way protect the joint from moisture. Therefore, it is used only as an addition to jute caulking. Sometimes the rope is stuffed onto log houses made of oak or larch, provided that inter-crown insulation made of red moss was used when assembling the bathhouse.

Included in the set

Most carpenters prefer to caulk walls this way. Its essence lies in the fact that a ribbon of flax or jute 10-20 cm wide is rolled out along the crown joint.

Then the upper edge of the strip is driven into the gap, and a set of additional tapes or a rolled braid is placed under it. After which the entire package is pressed end-to-end until the seal is completely pressed.

Stretch

An old method designed to use jute or flax tow. It is mainly used for large-sized log houses, when the total size of the seams inside and outside the bathhouse can reach a couple of thousand meters.

The essence of the method is that the tow is laid out in separate layers of fibers perpendicular to the joint line. The carpenter, as it were, stretches the pack lengthwise, adding or reducing the amount of tow, depending on the size of the gap. The method is more flexible than a set, but requires a lot of experience.

Log caulking technology

The main point of the procedure is to caulk as much sealing material as possible into the crown joint. The harder and smaller the caulk bead, the more reliable the seal. Any seal placed in a bathhouse frame degrades over time under the influence of water, heat and atmospheric oxygen. Therefore, the only chance to extend the service life is to caulk the material inside as densely and deeply as possible.

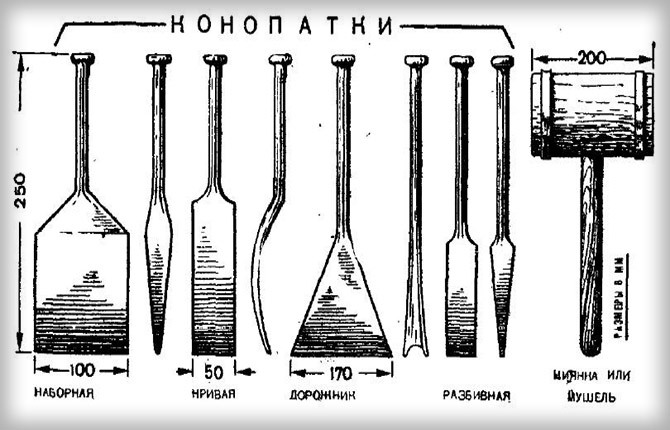

Required Tools

For work, several varieties of one main tool are used - this is the so-called caulk. The master always has several types with different blade widths and thicknesses, and the shape of the working surface. Some of them can only be pushed in by hand, but most have a steel sole (nickel) on the back and are designed to be struck with a hammer or sledgehammer.

For caulking, use heavy carpenter's hammers 1-2 kg with a short handle. Some craftsmen prefer to caulk with a heavy wooden mallet. Such an instrument does not produce a loud sound, there is no recoil on the hand when struck. Mallets are usually used to caulk bathhouse logs using tow. It is more “fluid” and plastic than jute tapes.

For do-it-yourself caulking of baths, tapes with a density of 500-600 g/m are used2.

Preparation

As a rule, work begins with inspecting the walls of the bathhouse and determining the amount of material required. Typically, for every meter of caulking of a log house, 1.5-1.7 m of flax or jute tape is required.

For large gaps, the consumption of compaction can double or triple, but part of the inter-crown joints of the log house can be completely covered with tightly packed logs. It is impossible to caulk gaps in pieces, so in those places where there are no cracks, preparation is carried out.

To do this, take a caulk with a thick and sharp tip and, with blows of a sledgehammer, open the joint enough so that at least one layer of jute can be pressed into it.

Main stage

After the gap has been opened along the entire length of the bathhouse wall, they proceed to laying out the material. To do this, the upper edge of the flax or jute tape is manually pushed into the slot along its entire length using thin caulk.

The material should go inside by 2-4 cm.

The next step is to place a braid or a package of two additional strips of flax under the laid tape and tuck the lower edge of the previously secured material. In this way, a roller (edge) of the seal is formed.

Next, you need to choose a tool with a thin and slightly curved blade. With its help, you need to caulk the lower edge of the tape inside the seam under the pigtail or an additional layer of flax.

This procedure is carried out with your hands without blows. As soon as the lower edge is pressed inward along the entire length of the crown of the frame, you can proceed to upsetting using a sledgehammer. Caulk with even strokes along the entire area. It is important that the material sinks evenly into the wall of the bathhouse, without distortions or hernias.

The procedure is considered completed in this area as soon as the width of the roller decreases to 4-5 mm.

Corner processing

Corner areas are sealed in a similar way. For each section, a separate piece of tape is cut out for the entire length of the corner joint. If tow is used, then it is laid with an overlap of at least 15 cm on a horizontal section.

It is advisable to caulk the corners using the lightest hammer. A strong blow to the end of the log can lead to chipping or cracking of the frame material.

Results

Caulking a log bathhouse with your own hands without practice is quite difficult. In addition, there is a lot of physical stress on the hands, so for the first experiment you can choose a small area where there are no windows or doorways. Only after practicing the techniques can you try to caulk inside the bathhouse.

Tell us about your experience sealing joints on log houses. What technology features should you pay attention to first? Also save the article to bookmarks and share it on social networks.