To maintain a certain temperature in the greenhouse using different heating systems. The choice of heat supply depends on the size of the building, the climatic conditions of the region, the availability of a particular type of fuel, financial possibilities and other factors.

Some home craftsmen are taken to organize the heating of the greenhouse with their own hands - this solution will significantly reduce the cost of labor, do you agree? Of course, an independent arrangement of stable heating is not an easy task, but it is quite realizable. The first step is to choose a heat source.

We will tell you what options of greenhouse heating exist, what are their specific work, advantages and disadvantages of use. Based on the above information, you can determine the type of heating, perform a preliminary calculation of the thermal power, select the working units and elements of the system.

The content of the article:

- Specifics of maintaining the temperature in greenhouses

-

Autonomous heating based on combustion

- Furnaces and solid fuel boilers

- Gas boilers and convectors

- The problem of air leakage and humidity

- Ways to evenly distribute heat

-

Popular heating methods without open flame

- Electrical appliances

- Heat release by biochemical method

-

Systems with external heat source

- Creating a separate heating circuit

- Exhaust air heating

- Conclusions and useful video on the topic

Specifics of maintaining the temperature in greenhouses

Heating of the greenhouse is necessary to compensate for heat losses that occur through the walls and ceiling of the structure, as well as due to the intake of outside air. To reduce heating costs, it is necessary first of all to properly heat the greenhouse and minimize air exchange with the street.

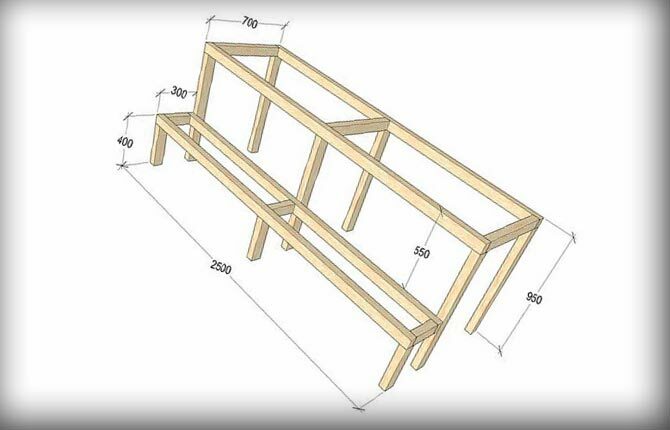

In addition to the material from which the greenhouse is made, special attention should be paid to the tight fit of the structure to the soil. For this, it is better, when erecting a greenhouse, to make a foundation with a small depth insulated from the inside.

It must reliably hold the structure in strong winds, prevent the formation of cracks and minimize heat exchange with the street through the top layer of soil.

To solve the latter problem, even in the conditions of the northern regions, 30 centimeters depth is sufficient, since the thermal conductivity of the soil is very low. The intensity of the vertical heat exchange between the soil layer inside the greenhouse and the underlying soil layer is very low.

In winter, snow can be used as a natural outdoor insulation along the edges of the greenhouse.

Snow is an excellent insulating material. However, the design of the greenhouse must be able to withstand the additional weight, and the material does not bend under its weight.

For normal plant growth, it is necessary to maintain the temperature of the air and the soil and plant layer in a certain range. If the greenhouse operates continuously, the fertile soil will be heated by heat exchange with the internal air. Moreover, its temperature will be almost the same as under natural conditions in summer.

In the winter, the soil and soil layers are frozen to a depth depending on the geographic location of the region and the structure of the rock. For warming up the soil and the upper layer adjacent to it before planting, it is necessary either very long (up to a month) to maintain a positive air temperature.

An alternative solution is to carry out special actions for the transfer of heat directly into the ground. This can be done with the help of a system of underground pipes into which coolant is supplied.

The amount of energy spent on heating the greenhouse depends on the following factors:

- The surface area of the walls and roof of the greenhouse. The smaller this figure, the less heat loss. Therefore, to save energy, it is better to use a rectangular or semicircular shape of the structure.

- Material thermal conductivity. The lower this parameter, the better the material retains heat.

- Temperature difference between indoor and outdoor air. The greater its value, the greater the heat loss.

- Air exchange through leaks. To reduce energy costs, it is necessary to eliminate the uncontrolled flow of cold air.

A large variety of projects of private greenhouses and the quality of their installation seriously hamper the modeling of temperature. Therefore, accurately determine the amount of energy required for heating a specific object can only be experimentally.

Such methods approximately calculate the required power of the heater. The problem lies in the difficulty of determining the dispersion coefficient for a specific object (+)

Autonomous heating based on combustion

Using the process of burning fuel as a heat source is the most commonly used method of heating small greenhouses. Such heating has some specifics, since it is necessary to take into account the increased tightness of the room, the desirability of heating the soil and the need to maintain humidity.

Furnaces and solid fuel boilers

One of the simplest devices used for heating greenhouses during the cold period is a furnace. The popularity of such a device due to cheap fuel. They can be uncalibrated firewood, dry grass, coal and coal dust, garbage and flammable liquids.

When furnace heating is necessary to provide a stable craving, since the ventilation of the greenhouse when injected into the combustion products will lead to its cooling.

When using a metal furnace, heating and transfer of energy to the surrounding air occurs quickly. It is also the cheapest and easiest to use heating method. You can build such a unit yourself.

On our website there is a selection of articles on the production of different types of metal furnaces that can be used to heat a greenhouse:

- How to make a furnace buleryian do-it-yourself: step-by-step instructions on how to make

- Gas stove from the gas cylinder do it yourself: diagrams, drawings + step by step guide

- The furnace for working out of the pipe: how to make an effective stove on waste oil from scrap materials

The stone stove heats up more slowly and keeps heat longer. It is more suitable for heating small rooms with an average or narrow range of permissible temperatures. However, such a furnace must be folded and, if necessary, cannot be moved as its metal counterpart.

There is an idea of heating the space in the greenhouse with the help of hot combustion products. To do this, they propose to place the stove in a hole, and to lay the chimney horizontally below the ground level and then exit it to the surface.

With this placement of the chimney there will be a significant increase in its length, as a result of which hot gases will give more heat inside the room.

This option really will increase the efficiency of heating.

However, in practical implementation the following difficulties will arise:

- Requirements for chimney assembly material. At the exit of the furnace, the air temperature is very high. Therefore, the chimney should not have a good heat transfer otherwise it will burn out the soil around it. Asbestos pipes can be used as a material for removal of combustion products.

- Compliance with the rules of placement of the chimney. In the chimney it will be necessary to provide inspection windows for cleaning it from soot. Therefore, you need to lay the pipe between the beds.

- The need for power supply. The long horizontal section does not contribute to the creation of normal thrust, so it will be necessary to install a smoke exhauster. This means the need for supplying electricity to the greenhouse or periodically recharging the battery.

Therefore, the idea of underground placement of the chimney in practice has not found wide application.

Instead of the standard furnace, you can use solid fuel. long burning boilers. They burn fuel more efficiently and do not allow for the rapid release of heat, which eliminates the possibility of damage to plants from high temperatures. Such factory-made boilers are easy to use and maintain, as well as compact.

Gas boilers and convectors

For greenhouses, the use of gas is a good alternative to stove heating. LPG boiler or convector. For small private facilities usually use equipment that works on the basis of gas cylinders.

Before installing a gas boiler in a greenhouse, it is necessary to thoroughly strengthen one of the walls to which it will be attached.

It is better to place the gas cylinder outside the greenhouse. But in this case it is necessary to solve the issue of preventing the freezing of the gearbox during a long period with a negative temperature.

Connecting the greenhouse to the gas network is a rather complicated bureaucratic procedure. In addition, with the annual mandatory inspection by a gas service specialist, comments will be made.

In any case, the presence of a combination of the gas supply and the use of open fire in a closed room requires increased security measures. The best solution is the presence of a gas analyzer, as well as a system of automatic fire extinguishing, triggered when the MPC of a combustible substance in air is exceeded.

From the standpoint of comparing financial costs when installing and using furnaces and gas equipment, it is impossible to make a definite conclusion. A simple gas convector costs about 12-14 thousand. rub.

It is more expensive than metal devices operating on solid fuel:

- the cost of metal and consumables for the independent production of the stove is about 3 thousand. rub;

- factory solid fuel installation of small dimensions, for example, the model НВУ-50 “Bulka” costs about 6.6 thousand. rub.

- A long-burning installation of the NV-100 “Klondike” model costs about 9 thousand. rub.

A stone stove will be more expensive than a gas convector due to the cost of foundation work and laying.

It is advisable to install a stone stove if it is certain that the greenhouse will be located at this place for years.

The cost of liquefied or natural gas spent on heating any room will be cheaper than purchased wood and coal. However, greenhouses are usually heated with free or cheap combustible waste, which is always sufficient in rural and country areas.

The problem of air leakage and humidity

The use of heating devices, in which there is an open combustion of fuel, leads to the need to remove combustion products through the chimney. In this case, compensation is required for the volume of exhaust air.

In buildings, it is possible through uncontrolled inflow (infiltration) which occurs due to the presence of cracks and holes in the walls and ceiling.

The design of modern greenhouses, such as polycarbonate, creates an airtight space. In this case, the problem of air intake is solved by the presence of vents and the installation of a special inlet.

It should be placed in such a way as to avoid a concentrated stream of cold air on the plants. It is also possible to use several small holes for organizing a distributed inflow.

Exhaust systems for closed-type gas convectors are already fitted with a pipe for intake of outside air into the combustion chamber.

In a convector with a closed combustion chamber, the outside air does not cool the room, and the combustion products cannot get inside (+)

Often after the operation of furnaces and boilers, the effect of air drying is observed. This is due to the lower absolute humidity of the incoming cold flow (especially frosty) in relation to the warm air leaving the greenhouse through the chimney.

To maintain accurate humidity parameters, a humidifier with a hygrometer is used, which can be operated from a local energy source. In the absence of such a need, an open container with water can be placed in the greenhouse. Then, in the case of a strong dehumidification of the air, the evaporation process will naturally occur.

Ways to evenly distribute heat

For small greenhouses enough to place a single source of heating. Air circulation in the room will be provided due to the vertical temperature difference and, thus, the distribution of warm air will occur.

In any greenhouse when it is heated, a slight vertical temperature difference occurs. This must be remembered when arranging thermometers.

In rooms with a large area or complex geometry, zones with different microclimate parameters may be formed. This is sometimes done in industrial greenhouses, but in most cases this phenomenon is undesirable.

For even heat distribution, two methods are used:

- Creation of artificial air circulation. Usually use impeller fans. Sometimes they construct a duct system with integrated pumps so that air is drawn at one end of the room and discharged at the other.

- Heat transfer through intermediate coolant. As a rule, an ordinary water system with forced circulation is used. Pipes can be laid both around the perimeter of the greenhouse, and under a layer of soil.

Forced heat distribution is also necessary to prevent the formation of a high temperature zone near the heater. Otherwise, plants located near the stove or boiler may receive thermal damage.

Popular heating methods without open flame

The use of open fire has some limitations, since there is a release of combustion waste, and it is also necessary to comply with fire prevention measures. Therefore, other methods are often used to release heat into the greenhouse.

Electrical appliances

Using electricity to heat a greenhouse in winter is the most expensive way. However, it is also the simplest, since the installation of such heating includes only wiring and installation of appliances.

The use of simple automation systems frees people from the need to participate in the constant control of the microclimate.

Wiring multiple heaters through the thermostat is quite simple. The only problem may be a power outage, so you need to provide for the connection of additional power sources (+)

Electric heating of the greenhouse can be performed using the following devices:

- Heater. The most simple and cheap device that can be made independently.

- Convector. The presence of the fan allows, in addition to heating the air, to make it evenly distributed throughout the greenhouse.

- Heat pump. A powerful device for heating air in large-capacity greenhouses, which is often used in conjunction with a duct system for heat distribution. For heating a compact room you can make heat pump on their own.

- Infrared lamps. The specificity of such devices is to heat the surface on which the radiation falls. Thus, it is possible to equalize the vertical temperature gradient in the room without the use of air circulation.

- Heating cable. It is used to heat local areas in the greenhouse.

In the case of small room size, the use of electrical heating is justified because of its simplicity and safety. In large and industrial greenhouses it is advisable to use other methods.

The heating cable is well suited for ground heating. Its maximum temperature is not high, so the effect of burning the soil with the loss of its qualities can not be afraid

Heat release by biochemical method

One of the interesting ways of heating is the application of unfermented organic fertilizer into the soil - animal dung or bird droppings. As a result of the biochemical reaction, a large amount of energy is released, which increases the temperature of the fertile layer and the air inside the room.

When manure decays, carbon dioxide, methane, and a small amount of hydrogen and hydrogen sulfide are released. Also manure has a specific smell. All this imposes certain restrictions on its use associated with the need for airing the room.

In winter, as well as during prolonged cold snaps in spring and autumn, intensive air exchange is undesirable. In this case, the restoration of heat balance after ventilation may require significantly more energy than was allocated as a result of the manure rotting process.

The use of such a “biological” method of heating the earth and air is justified in the late spring, when ventilation occurs at positive daytime temperatures.

Systems with external heat source

Heating of the greenhouse is possible due to the proximity of the house or other heated buildings. This simplifies the entire procedure, since there is no need to install an independent source of heat. With the help of wired or wi-fi relays, you can remotely receive information about the temperature in the greenhouse and regulate its microclimate from home.

An ordinary wi-fi temperature system consisting of a sensor and a relay costs about 2 thousand. rub. When the temperature exceeds the acceptable range, it transfers its values to devices running Windows or Android

Creating a separate heating circuit

If the house uses water or steam heating, it is possible to create a separate circuit leading to the greenhouse. It is necessary to provide it with a separate pump, since the total horizontal extent of the new segment will be great.

Also in the greenhouse you need to install an open expansion tank to divert air from the system. The open water area of the tank must be minimized in order to prevent the intense evaporation of hot water into the interior.

Radiators in a greenhouse are rarely installed, since the design of its premises plays a secondary role. With a lack of heat, it is better to lengthen the contour of the pipe, since it is cheaper and reduces the risk of leakage and breakage.

The street segment of the circuit must be insulated to avoid heat loss and minimize the risk of freezing. The underground pipe placement is best suited for this purpose.

Connecting a greenhouse heating segment to a common circuit can be made using a three- or four-way valve.

Standard wiring diagram for additional heating circuit. The location of the taps in the house allows you to remotely control the air temperature in the greenhouse (+)

It is also possible to create an automatic temperature control system.

This can be done in the following ways:

- The change in the volume of hot water to be passed depending on the readings of the temperature sensors. In this case, you need to purchase a pump with power adjustment.

- Turning the greenhouse heating circuit on and off. For this purpose, automatic crane control systems are used.

Instead of manually changing the position of a three-way or four-way valve, you can use servo-based devices. Its electronic control unit is adjusted to readings placed in the greenhouse. temperature sensors.

If necessary, change the heating mode receives a control signal to the engine, which rotates the rod, setting a different position of the valve.

Servo for automatic adjustment is large relative to the crane. Therefore, for its installation it is necessary to move the heating pipe from the wall

Exhaust air heating

Good heating can be obtained through the use of warm air exhaust ventilation of a residential house. Directing the insulated ventilation duct inside the greenhouse you can get a constant incoming flow with a temperature of 20-25 ° C.

The only condition is the absence in the air of excessive humidity and impurities characteristic of kitchens and bathrooms.

The outflow of air from the greenhouse can be organized in two ways:

- Local exhaust opening to the street in the form of a tube without a fan. It should be a small section to create a high flow rate. In this case, at a negative outdoor temperature, the zone of formation of condensate will be located at some distance from the tube, which will prevent the formation of ice.

- Returning the flow back with the help of an additional air duct and its obligatory connection to the general house hood. Otherwise, smells from the greenhouse will be distributed throughout the premises of the house.

This method is the most economical in terms of one-time costs for installation of the system and periodic costs for the use of fuel. The only question remains sufficiency of exhaust volume to maintain the required temperature. Check it out better experimentally.

If sometimes, during extreme cold snaps, the air temperature in the greenhouse will fall below the permissible temperature, then You can install a small heater in the air duct, or install an additional electric device on the the object.

Conclusions and useful video on the topic

Homemade stove with a long chimney for heating greenhouses:

Several options for wood stoves in a real greenhouse:

Gas burners as a source of heat. Plumbing for greenhouses:

There is no universal option for heating a greenhouse. The choice in favor of one of the methods or their combination must be made taking into account its reliability, low cost of installation and use of equipment, energy prices and autonomous duration work.

Most projects can be implemented on their own, which will reduce their cost and provide an opportunity for further self-modernization.

Do you have personal experience in the design and arrangement of heating in a greenhouse? Want to share your knowledge or ask questions about a topic? Please leave comments and participate in discussions - the form for reviews is below.